7 Improve Implementation

Objective: This step provides a comprehensive approach to improving the use of construction robotics throughout implementation and use on a project.

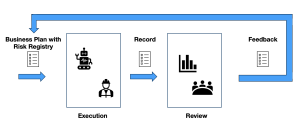

Figure 7.1. Process of Improve Implementation

Effective robotic planning requires continuous assessment and refinement to maximize the benefits of automation. The following structured improvement process allows project teams to monitor critical performance metrics, analyze the impact of robotics on the specific construction site, and make data-driven adjustments that allow for construction improvement.

Record Robotics Performance and Project Performance:

Tracking both the robotics and the project performance is crucial to understanding changes that should be made to achieve continuous improvement during the implementation of construction robotics. Recording data across areas such as the number of workers involved and a robotic performance (safety, cost per unit production, schedule, and quality) can allow project teams to identify potential improvement areas or consider removing constraints. It is recommended that this information be tracked weekly to accurately capture all of the metrics listed above. A blank worksheet can be found in Appendix K.

The criteria and targets for this table should be project-specific and representative of the project goals the team is working to achieve. The column allows the project team to enter the observed/actual performance for the week, and the variance column should show the difference between the target performance and observed/actual performance. The comments/notes column can be used to list any important information that may have affected the observed performances, and the overall notes section can discuss any noticed trends in the collected data.

Review and Improvement:

After gathering the information discussed, the project team can start discussing how improvements can be made in robotics implementation. Ensuring that areas where goals are met or exceeded stay on track and do not backslide is crucial. Backsliding can occur for a wide variety of reasons, such as crew member changes, site delays, miscommunications, lack of access to key information, etc. Areas that are not meeting the target goal have the potential for improvement and should be especially examined. It is key to consider ways to improve, potentially with additional training, organization, site logistics, etc. Based on this review, a new business plan can be created to run the Plan-Do-Check-Act (PDCA) cycle. PDCA cycle is a continuous improvement cycle widely used in construction and other industries to enhance project processes, quality, and performance. The revised plan should be communicated well, as stated in Chapter 6.

Document for Future Use:

The final phase of this process lies in documenting this robotics implementation plan for future use. The project team should communicate the improvement strategy throughout the organization or company and coordinate with ongoing projects that may be considering using construction robotics. It is important to consider whether using construction robotics is a project decision or a company-wide decision, as then multiple projects may need to coordinate together to ensure procuring the robot will be valuable.