Executive Summary

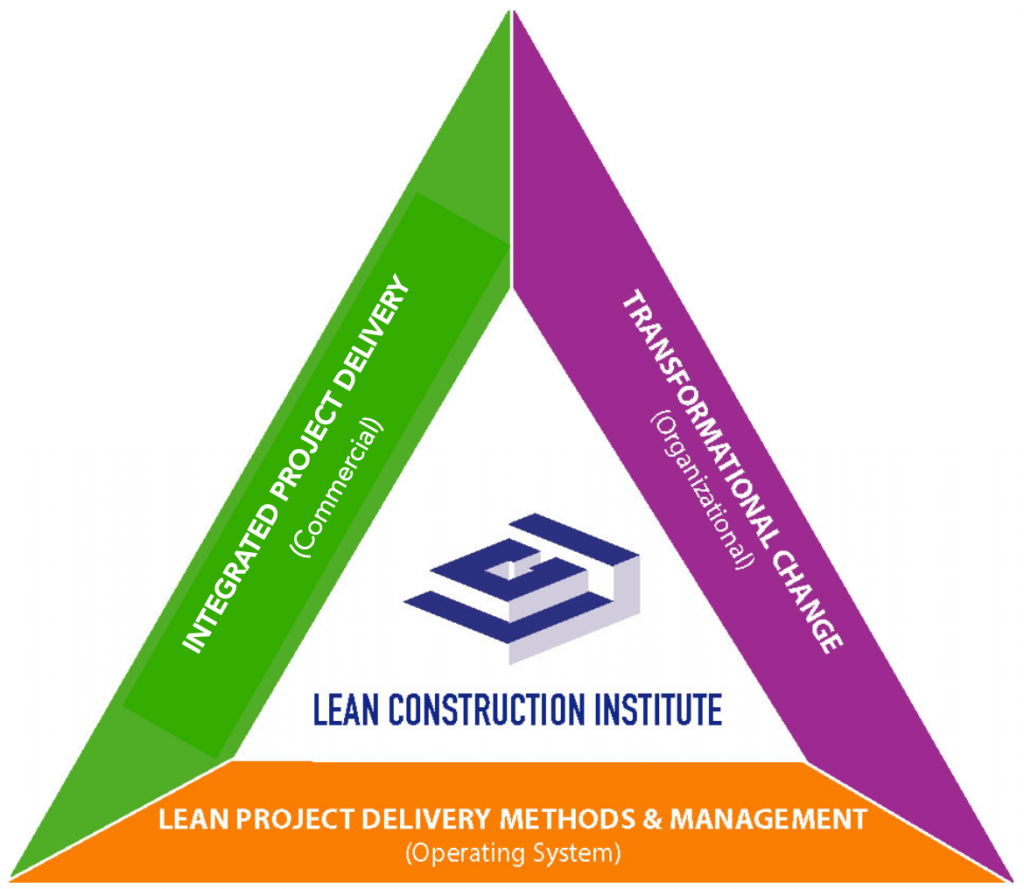

The core principles of lean construction are respect for people and continuous improvement by focusing on process improvements and flow of efficiencies, thus eliminating waste and creating value in facility delivery. Encompassing all lean principles, the overarching goal for implementing lean construction is to focus on continuous improvement of people, process, and product as we deliver construction projects. This can be achieved by implementing lean holistically on a project by focusing on the commercial structure (i.e., the business), the organizational structure (i.e., the culture), and ultimately, the operating system (i.e., the project) as shown in the LCI triangle (see Figure 1) (LCI, 2010).

The purpose of this guide is to support a project team putting in place their operating system once their commercial and organizational structure has been established for the project. Developing a lean deployment plan for a project can help project teams to plan the lean principles and practices throughout the stages of a project by embedding them into the project management processes, ultimately delivering better value for clients while simultaneously improving overall safety, cost, schedule, and quality. The lean deployment plan is ideally meant to be developed by the project team collaboratively with a commitment to the resources and competencies needed for lean implementation, following the formation of the project team and, the development and validation of the project’s business plan.

A Lean Deployment Plan is defined as a formal plan that outlines: the project’s conditions of satisfaction, the selected methods, the plan for each method, and finally the consolidated project plan, which will be implemented to improve value creation and develop the strategy for communicating and learning from the implementation.

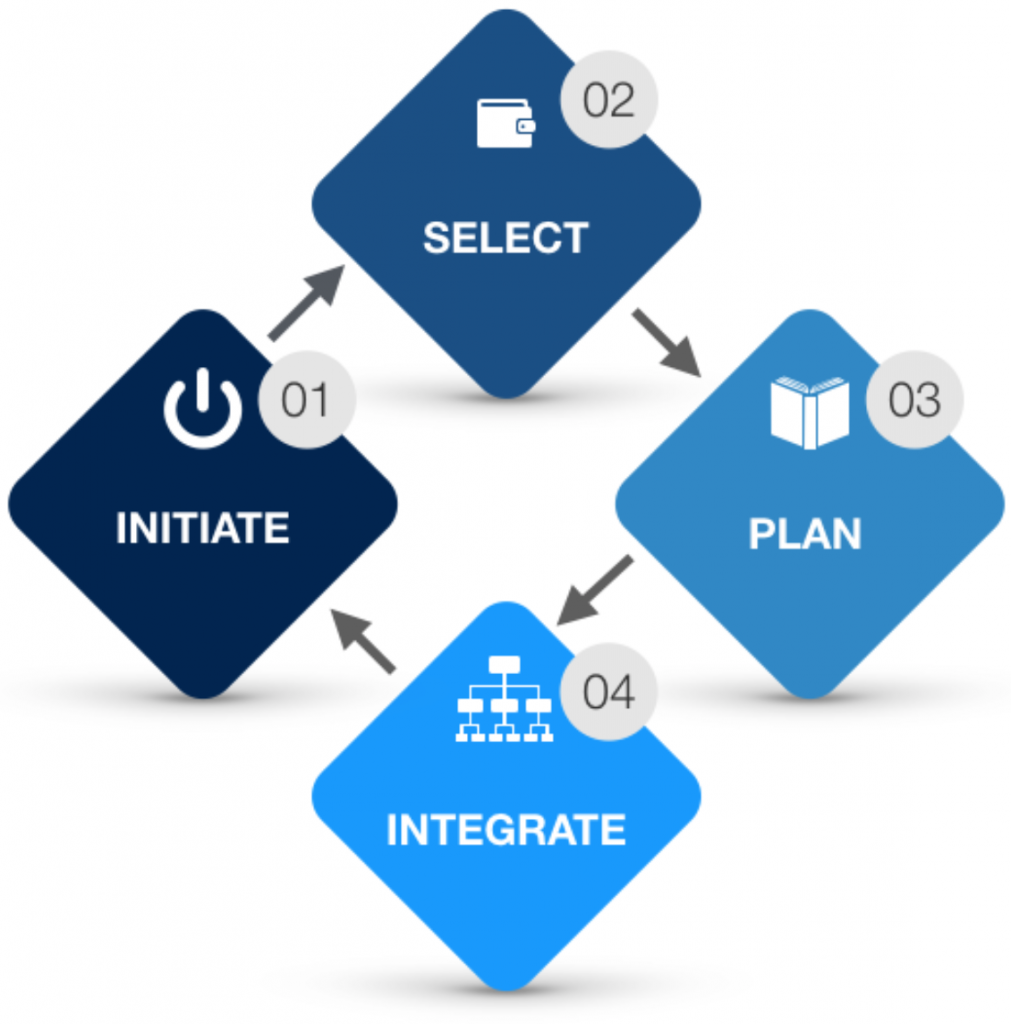

Research shows that applying lean on projects leads to improved safety, higher quality construction, reduced project schedule, greater productivity, and last but not least, better risk management (McGraw Hill, 2013). However, adoption of lean principles into a capital project is challenging because each project brings together team members with a vast array of experience, abilities, and knowledge, and different levels of awareness and experience with lean principles and methods. Therefore, this guide is designed to walk the project team through four steps (Figure 2) of the planning procedure systematically as you create your project specific Lean Deployment Plan, while encouraging discussion of lean principles and methods on the project. Each step in the procedure is defined and described in detail in the following chapters of this guide. Template resources are provided to help project teams work through the planning procedure, and document their project-specific lean deployment plan.

Using the plan the project team will be able to develop a common understanding of how lean will be deployed, communicated, measured, and improved supporting the project’s conditions of satisfaction. The development of this common understanding can be achieved by collaboratively identifying the strategies and methods that serve the project requirements and then plan for their execution. As the project team works through the planning procedure, the templates provided within the guide are designed to help facilitate and document a complete plan for lean implementation. Therefore, it is beneficial for the team to collaboratively work on this plan, recording all the critical decisions that led to determining the project conditions of satisfaction, selecting methods, tracking implementation, defining the education and training strategy, communicating the plan, and improving continuously.

Audience

The Lean Deployment Planning Guide is designed to help project teams interested, or required by the project client or owner organizations, to implement lean strategies and methods on their projects. This procedure can also be used by a lean coach or a lean consultant to promote and manage the consistent implementation of lean principles and methods at a project level. It gives the project client or owner a place to start, informing them about what to ask for from projects implementing lean. Overall, the primary audience for this guide is the team recruited for a project, whether a group of individuals interested in adopting lean or a group of firms engaged in a project.

Intended Use

This guide is intended to be used as a reference in the early stages of project planning that can assist project teams to work through the procedure using the attached template resources to define their project-specific lean deployment plan, capturing the baseline for continuous improvement in current as well as across future projects. At project initiation, when key stakeholders are engaged, this guide and additional resources can be used as tools to perform a lean soft-start or lean deployment planning kick-off. The guide will serve the project team to develop a project-specific lean plan by orienting them to the lean methods that can support the project’s conditions of satisfaction. Throughout the project lifecycle, the project’s lean deployment plan, developed with the help of this guide, can also be used as an on-boarding tool and build a common understanding between new and existing members of the project team. The planning procedure in this guide can also be used to conduct training workshops for lean project planning or even method implementation planning.

Maintenance

Finally, the plan developed with the help of this guide is meant to be a living document and can be revisited to further improve or refine content as needed to maintain the successful implementation of lean principles and methods that fulfill the project’s conditions of satisfaction. With a sufficient number of implementations using the guide, we envision the ability to benchmark projects managed using lean principles and track owner organization-level or even industry-level improvements.