5.4 Drill Bits and Recovered Cores

Once the core was brought on to the area of the ship referred to as the catwalk, the marine technicians started preparing the core to be moved into the laboratories. Each expedition crew always worked towards full core recovery during the drilling process, but any core material recovered was a valuable addition to the sample collection and allowed scientists to advance our knowledge of the deep sea. Look through the photo gallery below to see some of the cores that were brought into the lab after being taken from the rig floor.

Photo 1: First core on deck for an expedition, showing the core right after it is brought on board the JR to an area known as the catwalk (Credit: Jennifer Field). Photo 2: Brittany Stockmaster (Marine Laboratory Specialist), left, and Aaron Mechler (Marine Laboratory Specialist) carry core sections from the catwalk into the core lab. (Credit: Tiffany Liao). Photo 3: Beth Novak (Assistant Laboratory Officer) organizes the hard rock core pieces in the core liner. (Credit: Tiffany Liao). Photo 4: Scientists explore the color variation in cores after being split. (Credit: Carlos Alvarez Zarikian). Photo 5: Isuri Kapuge (Sedimentologist, University of Delaware, USA) scrapes the surface of a core section half. (Credit: Adriane Lam). (All photos from IODP MerlinOne photo archive, CC BY 4.0)

The intervals of drilled core fit into 9.5-10-meter (31-32.8 foot)-long tubes, and the technicians cut each retrieved core tube into roughly 1-meter (3.28-foot)-long sections. The higher the core recovery during the drilling process yielded more sections to photograph, measure, sample from, analyze, and more. For example, if there was 100% recovery, than 10 sections were cut for that one core. There was a lot of work for technicians and the scientists to do once the core arrived on deck. Each expedition had multiple drill sites, and multiple bore holes per drill site. Drill sites offered a location that provided insight to what geologically was happening in that area, while multiple boreholes provided more precise knowledge to the drilling crew and science crew of what to expect at certain depths to better inform drilling and coring processes. For instance, boreholes were drilled next to each other to increase overlapping evidence of seafloor formation, which would increase recovery rate. Additionally, multiple boreholes was a common practice when dropping CORKs, free- fall funnels, or reentry cones so a drilling site could be returned to.

After each expedition, it was up to the science team and the members of the JOIDES Resolution Science Operations team to produce a preliminary report that identified the multitude of research and drilling tasks that were completed. All the data relating to the cores were put into a operations summary table. These data included drill sites, the number of bore holes per drill site, the depth for each bore hole, the estimated age of a borehole, the coordinates of the borehole, at what depth hard rock was reached, and more. Though very detailed to collect, it is crucial to the research that is conducted in the years post-expedition for the onboard and onshore scientists that access the online database of core information.

What Do Cores Look Like?

After reading about the equipment and ways in which JOIDES Resolution drilled and cored, it is time to start looking at some cores.

Below are examples of cores retrieved from soft, hard, and extremely hard formations. The details for each core image were sourced from scientific ocean drilling preliminary reports. Keep in mind that core appearances can vary for multiple reasons beyond just the depth of material. For additional information about the drill bits and coring techniques, visit the Coring Equipment and Tools page.

Advanced Piston Coring (APC) Cores: Soft Formations

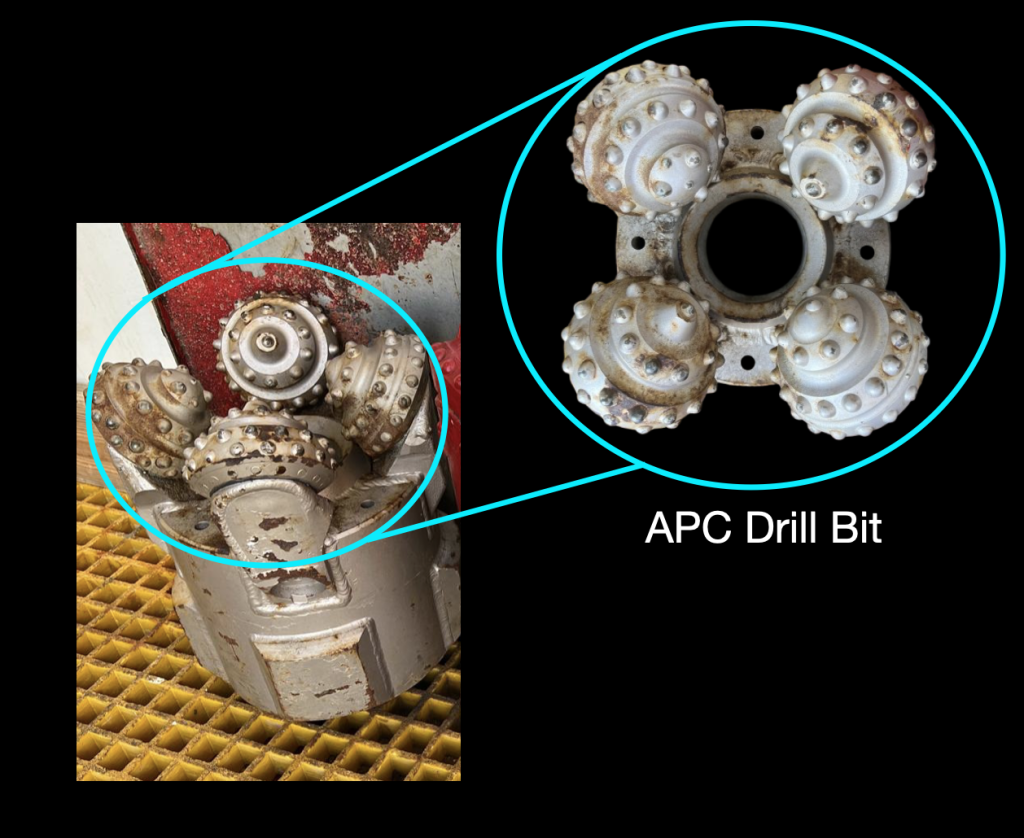

Soft formations reference the soft sediment layers that sit on top of oceanic crust. The type of equipment used to drill and core for soft sediment is the Advanced Piston Core Barrel. This drilling technique has the drill bit hover slightly above the layer of sediment and rapidly punch through the seafloor to collect the core. This reduces the mixing or disturbance of the fine sedimentary layers. Below is an image of the drill bit where the APC core barrel would sit in the middle of (the hole in the middle in between the rotary cones).

Exercise: Sediment Cores From IODP Expeditions 393 and 385

These images are from cores recovered in Expedition 393 (Core 1) and Expedition 385 (Core 2). Click on the small gray dot below the image you are viewing to see the other core. Examine both and answer the questions below:

a) What kinds of observations can scientists make by examining the images of these sediment cores?

b) The white blocks with letters indicate that samples were taken for specific types of destructive analyses—tests that alter or destroy the sample during data collection, meaning it cannot be returned to the core. Why is it important to show in the core image which sections were removed for these analyses?

c) Using the scale along the side of the image, can you estimate how much of the core was recovered for either core shown above?

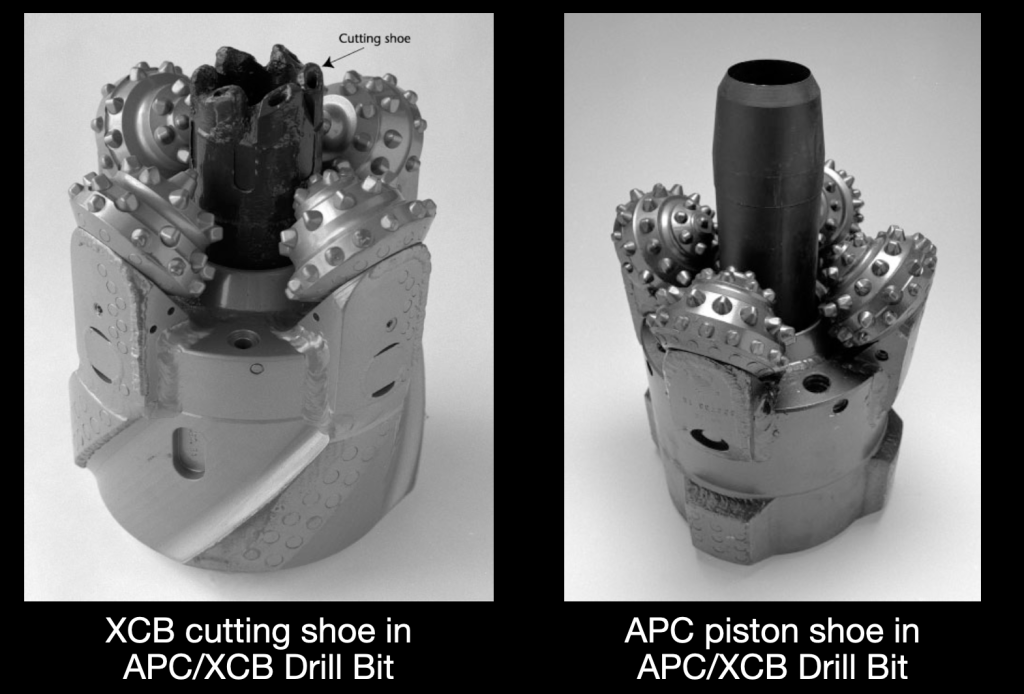

Extended Core Barrel (XCB) Cores: Hard Formations

Extended Core Barrel (XCB) coring uses the same drill bit as the Advanced Piston Corer (APC) but employs a different cutting shoe. The cutting shoe is the part that actually cuts the core. As drilling progresses into deeper and harder formations, the XCB cutting shoe performs better than the APC because it is designed to cut, rather than punch through the seafloor material. While the APC cutting shoe punches through softer sediments, the XCB cutting shoe gradually cuts the shape of the core once drilling reaches about 9.5–10 meters (31–32.8 feet) and continues to be used in deeper, harder formations.

The images below show examples of each method. Photo 1 shows a core from IODP Expedition 392, retrieved using an XCB cutting shoe. The previous nine cores from this drilling site were obtained with half-length APC cutting shoes (HLAPC). Photo 2 is of a core from IODP Expedition 385, retrieved using an APC piston shoe. This core was the eleventh out of 18 cores from this site. At Core 15, where drilling reached harder formations, the crew switched from the APC to the XCB cutting shoe.

Rotary Core Barrel Cores: Hardest Formations

Rotary Core Barrel (RCB) cutting shoes were the equipment used to core through the hardest formations. The cutting shoe would sit within the larger drill bit and the majority of the cutting was performed by the drill bit rotary cones.

Exercise: Hard Rock Cores From IODP Expeditions 393 and 385

These cores were retrieved by a Rotary Core Barrel drill bit and are examples of relatively good recovery. These images are from cores recovered in Expedition 393 (Core 37) and Expedition 385 (Core 8). Click on the small gray dot below the image you are viewing to see the other core. Examine both and consider the questions below:

a) What factors do you think could influence the recovery of a core, especially if it is hard rock?

b) What observations can the scientists make on these hard rock samples, versus observations they could make on sediment samples?