5.3 The Coring Process

Before we launch into the details of the coring process, take a look at this video for a brief overview.

Scientific ocean drilling vessels like JOIDES Resolution were designed to collect physical seafloor samples via cores by connecting the ship at the sea surface to below the seafloor via a drill string. Unlike oil and gas drilling, which aims to destroy and extract, scientific ocean drilling preserves sediment and rock samples. While the processes may look similar, scientific drilling operates at a slower pace to avoid damaging the seafloor samples, named as cores. Depending on the depth, one drill site can provide numerous cores and numerous holes.

How Did Coring Work?

On JOIDES Resolution, the coring process began as the rig floor crew assembled the drill string, a process called “tripping pipe.” The drill string was lowered through the rig floor and the moon pool decks, passing through two sets of guide horns that stabilized the pipe and prevented it from striking sharp edges as the ship moved with the sea. The first guide horn was located between the moon pool deck and the rig floor, while the second sat inside the moon pool. The moon pool’s position directly under the derrick ensured minimal bending as the drill string was deployed.

Over approximately 12 hours of tripping pipe, the drill string was gradually lowered toward the seafloor. Since the crew had an estimated water depth, they could determine the number of pipe stands required before reaching the bottom. As they approached this estimated depth, the driller within the drill shack, often called the “dog house” on the ship, carefully monitored the weight on the drill bit and any resistance to confirm contact with the seafloor.

More on the DogHouse

The Doghouse, or more professionally referred to as the Drill shack, was where the driller could keep watch and manipulate many different characteristics of drilling process. They had monitors to watch the camera feeds from different angles of the drill floor, especially high up in the derrick, and to watch the digital output of RigWatch. Rigwatch was a computerized visualization of the drilling process, but the driller watched the dials more closely as that is where they could gauge how much they were manipulating the drill. The window was in a direct line of sight to the rig floor and the drill pipe. Watch this video here to learn in more detail what Driller’s focused on while on shift.

Once the drill string reached the seafloor, the rig floor crew prepared two core barrels. Each barrel contained a plastic core liner and was fitted with a predetermined cutting shoe. One core barrel was sent down the drill string to begin coring, while the second waited on deck, ready for rapid deployment. The type of core barrel used depended on the drill bit and bottom hole assembly (BHA):

- For the APC/XCB drill bit, the APC or XCB core barrel was deployed.

- For the RCB drill bit, the RCB core barrel was deployed.

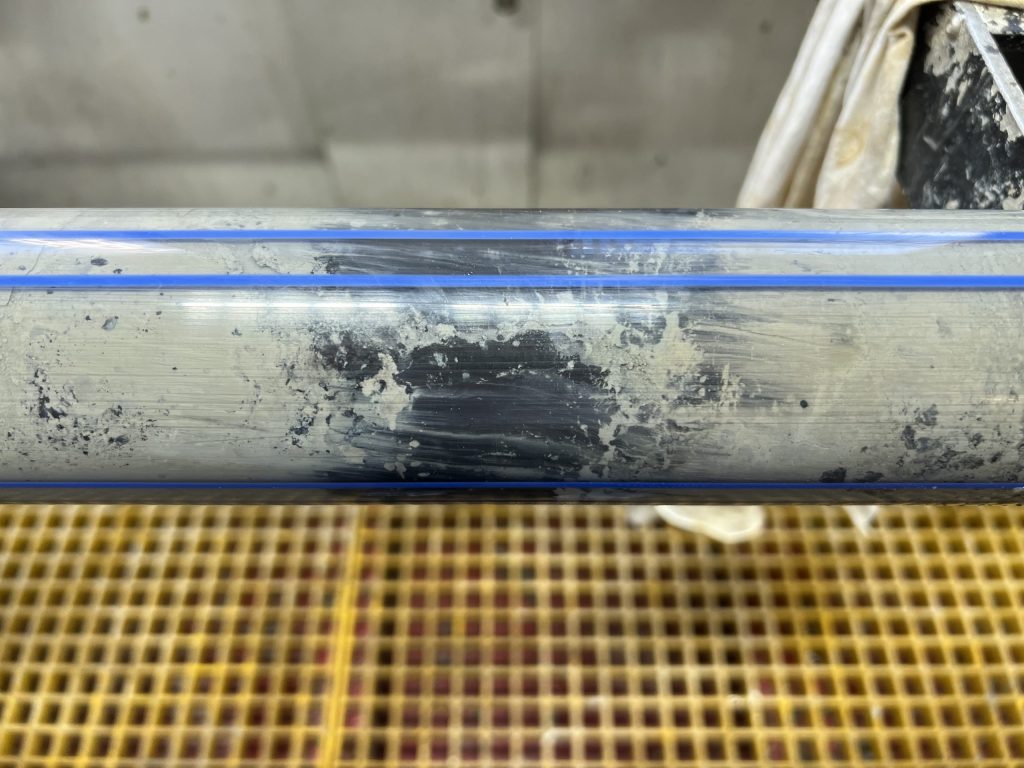

A key point is that the core barrel, not the entire drill string, moved vertically in and out of the borehole repeatedly during coring on JOIDES Resolution. The drill string remained in place as additional pipe stands were added to reach greater depths. Once the core barrel penetrated about 9.5–10 meters of seafloor (or 5 meters for half advanced piston coring), the rig floor crew sent down a latching tool that hooked onto the top of the core barrel. This tool was then winched back up using a separate line from the drill string winch. The amount of core recovered was confirmed only after extracting the core liner from the core barrel. The driller received real-time data on coring performance from instruments in the drill shack, but visual confirmation came from the recovered core.

Sending and Receive a Core Barrel

Efficiency is crucial in scientific drilling, so the rig floor crew always had a second core barrel prepped and ready to be deployed as soon as the previous core was retrieved. This process unfolded as follows:

- Core Barrel Retrieval

Once the core barrel reached rig floor height, the iron roughneck (covered in the previous section) unscrewed a pipe stand joint. The rig floor crew attached a new winch line to the recovered core barrel, pulling it out of the drill string and storing it nearby.

- New Core Barrel Deployment

A freshly prepared core barrel was immediately inserted into the drill string and released to plummet to the seafloor for the next coring run. At this point, the rig floor crew determined whether to change the cutting shoe for harder formations. If needed, the on-deck core barrel was adjusted accordingly.

- Securing the Drill String

The iron roughneck was used again to torque the pipes together, ensuring that they remained tightly connected during drilling. Only after securing the drill string was the recovered core barrel laid down, allowing the core liner to be removed and passed to the science crew on the core deck for analysis.

This entire sequence—from retrieving the core barrel to deploying a new one—typically took 15 minutes or less, ensuring a steady flow of cores for scientific study.

Watch the following video to see the process of bringing up a full core barrel and sending down an empty one to keep the coring process continuous.

Bring everything you learned together in the activity below.

SciOD Spotlight – Glenn Barrett, Toolpusher

JOIDES Resolution had two crews that alternated their time on the ship every expedition (for example, crew A would sail and work for two months, then take two months off while crew B was sailing), and each of the crews had two toolpushers. One person took the day shift while the other person took the night shift so that they could overlap with the entirety of the drilling team.

Note that the profile below about JOIDES Resolution toolpusher Glenn Barrett was authored while he was sailing on the JR in 2022.

Read the SciOD Spotlight below, then answer the following questions:

- What roles and responsibilities does a toolpusher have?

- What do you think is the importance of a handover during shift change?

- Why might it be useful for the toolpusher to liasie with the science team after core recovery?

Hi,

My name is Glenn Barrett, I am a petroleum engineer and I am the day shift Toolpusher and Core Tech on the JR. I am from Australia, and currently live in Texas, USA, where the science program is based, in College Station, although I do not work for IODP or the program, but for the JR’s owner, SIEM Offshore.

So, what is a Toolpusher and Core Tech, and what do I do?

Great question and well asked. A Toolpusher is a very old title for the Drilling Operations shift supervisor. It is an old Oil & Gas industry term, and almost all of the drilling crew here on JR are from an Oil & Gas background, as the mechanics of drilling our holes for the cores, are basically the same as drilling a hole looking for oil and gas. So, I am in charge of the drill crew (5 people directly, and many more indirectly at my disposal depending on the specific operation at the time), and executing the science drilling plan, on the day shift. The Core Tech title comes from the other half of my job. I also assemble and maintain the specific equipment we have on JR that drills and captures the cores, and recovers them back to the ship from sometimes 5 km away, for IODP and scientists, from around the world. I also maintain the physical inventory of parts needed to drill and core, and ensure we never run out and have to stop the operation. Daily I work with member of other departments onboard, to help them support the drilling operation.

A typical day on JR for me? There is no typical day!

My shift is officially 6:00 AM to 18:00 PM.

I wake around 4 AM every other day, and hit the gym for 20-30 minutes of cardio; usually on the rower or spin bike.

After showering and dressing, I am in the galley for breakfast just after 5 AM, and then to my office by 5:30 AM.

From 5:30 AM to 6:00 AM, I “hand over” with the Night Toolpusher/Core Tech who informs me of how the operation is going, along with what other maintenance and planning for upcoming ops has taken place during the night. We discuss work coming up, and crew safety and welfare until 6:00 AM, when he finishes for the day and I head to the rig floor to check in with the Driller and crew, to see how the operation and work is progressing.

From here on, my day is spent answering emails about operations and parts supplies, ensuring the drilling operation is carried out in a manner that maximizes safe core recovery; safe for the crew and the ship. Without a crew or ship, we couldn’t get core, so recovering as much core as possible, safely, is the priority.

As the Core Tech, I also help the crew recover the core and hand it over to the science techs from IODP (International Ocean Discovery Program), and then the crew and I reload and dress the coring equipment for the next core, so that we are continuously prepared and ready for the next core.

After a core comes up, I will liaise with the OIM (Offshore Installations Manager, my direct boss), IODP Operations Rep., and Chief Scientists, and together make decisions and changes to our coring and drilling parameters, based on the core we are recovering, seeing or anticipate seeing. In shallow water and soft sediment, we may get 4 cores an hour, but in deep water and hard rock, like basalt, we make get a core every 5 hours. Every expedition, site and hole is unique and different and has its own challenges.

I also relieve the driller for breaks, by standing in and doing the drilling for him, whilst he takes a mental and physical break from his console.

At the end of my day, I write a report of what has happened that day, and what is planned to happen, and at 5:30 PM, I hand over to the Night Toolpusher and finish my shift.

After shift, I work out with some weights in the gym, before a shower, and then either a call home to my wife, or read a book, or socialize with off shift crew at a movie or games night onboard.

Bed time is between 9 PM and 9:30 PM for a nice 7 hours sleep, before I am up and doing it all again.

I hope that gives a brief and broad insight into me, my job and a typical day out here on JR while we are coring for science.

Glenn Barrett, Toolpusher Afloat

SRV JOIDES Resolution, SIEM Offshore

[This profile was adapted from JR EXP 397T blog post So, What Is A Toolpusher? , authored by Glenn Barrett, posted and published by Onboard Outreach Officer Maya Pincus September 29, 2022]