17 Chapter 17: Introduction to Project Management and Control

Learning Objectives

After reading this chapter, you should be able to:

- Describe the many aspects of a project that need to be managed to ensure a successful construction project

- Define four management areas that are frequently referenced as the Golden Triangle, which require close management of constraints and expectations

Introduction

The construction industry is a project-based industry where a project can be defined as the lifecycle delivery of a capital facility. It is critical for all participants on a project to be familiar with project management. The definition of a project may vary depending upon an organization’s role within the delivery process. For example, to a design firm, a project may be defined as the design of a facility. Within that design firm, there would be a project manager who oversees the design process, who may have the title of Design Manager or Project Manager. Within a construction company, they may define a project to include the planning and implementation of the construction process for a project, and they would have a lead construction project manager assigned to the project. Regardless of the scope of a ‘project’ to an organization, there is a fundamental set of items that are critical to successfully implementing a project.

Knowledge Categories of Project Management

Construction Projects are not the only types of projects. There are many different industries that need to manage projects. Examples include software companies that view software products as projects. Or the shipbuilding industry that views each ship as a unique project. Or the space industry that views each launch vehicle as a project. Managing projects can be divided into a common set up project management knowledge areas. The Project Management Institute (PMI) is an industry association that has defined these knowledge areas. PMI has created the Project Management Body of Knowledge which defines the following core knowledge categories:

-

- Project Integration Management

- Project Scope Management

- Project Schedule Management

- Project Cost Management

- Project Quality Management

- Project Resource Management

- Project Communications Management

- Project Risk Management

- Project Procurement Management

- Project Stakeholder Management

They also added the following within a construction addendum, although one could certainly argue that some of these areas are common to other projects as well:

11. Project Safety Management

12. Project Environmental Management

13. Project Financial Management

14. Project Claim Management

PMBOK is a great resource for identifying each of the steps that should be performed within the management categories. It is also important to note that some management approaches cover multiple areas, e.g., cashflow analysis can be used for both cost and schedule management.

As you can see, there are many areas that must be managed on a project. Each of these areas has a planning, an implementation, and a documentation and reflection aspect to them. Within this course, we will specifically focus on four primary management categories during the project execution, although these are certainly not the only items that need to be managed, as defined in PMBOK. The four areas that will be highlighted in future chapters include:

- Safety Management (always of paramount importance)

- Cost Management

- Schedule Management

- Quality Management

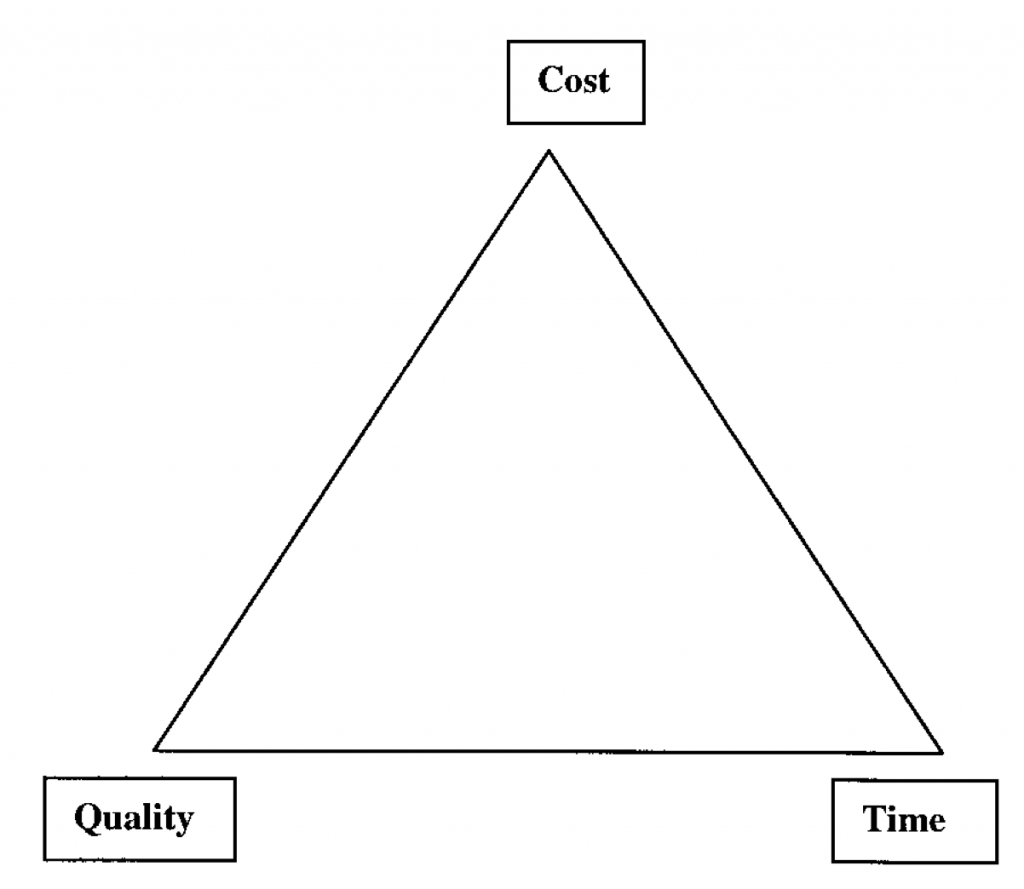

The Iron Triangle:

When we look at project success, Many people have defined three of the four (Cost, Schedule and Quality) within the context of the Iron Triangle. The International Project Management Association (IPMA) states that project management success relates to delivering the project’s product in scope, time, cost and quality (IPMA 2006). Atkinson (1999) discussed a metaphor of the Iron Triangle with a focus on Time, Cost, and Quality. You can certainly argue that you can not maximize all three at the same time, within a defined scope. One would hope that you can achieve the desired scope, within the budget, time and quality constraints, but you can not maximize all at the same time.

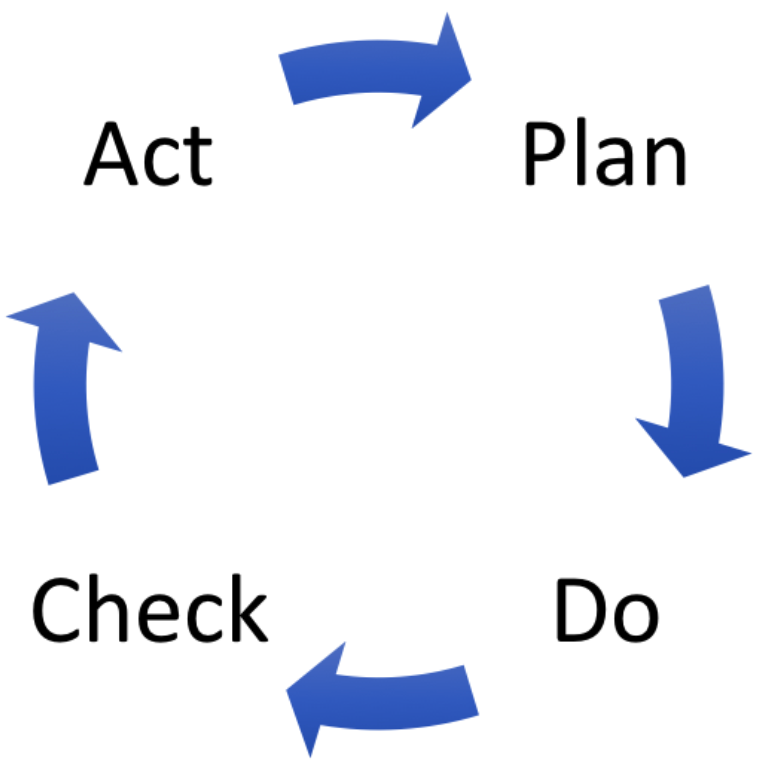

Plan – Do – Check – Act Cycle

The Plan – Do – Check – Act (PDCA) Cycle is a straightforward approach for effectively managing and controlling a process. PDCA has been discussed frequently within the lean management community. PDCA is focused on ensuring a continuous improvement process for a project. A simple description of PDCA is included at https://theleanway.net/the-continuous-improvement-cycle-pdca

Within the PDCA Cycle, the planning is focused on identifying problems and developing potential solutions, along with experiments to test the potential solution. Within the ‘Do’ task, an approach is implemented and data is captured for further analysis. Within ‘Check’, the data is evaluated to see if the solution worked. And finally, within ‘Act’, the team can determine if the issue is resolved, or if another cycle should be performed. One of the main goals of implementation of a PDCA approach within an organization is to develop a culture of problem-solving throughout the organization, supported by structure experimentation.

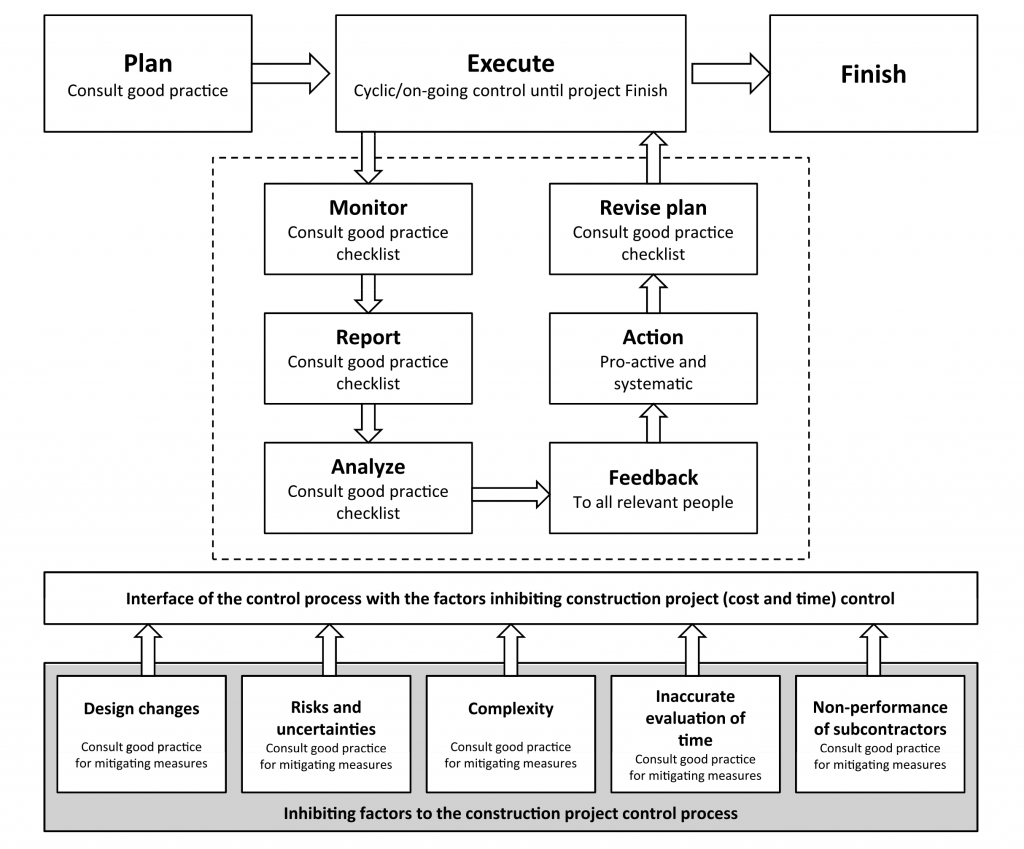

The Project Control Process

One part of project planning is the development of the original plan.

References:

Atkinson, R. (1999). Project management: Cost, time and quality, two best guesses and a phenomenon, its time to accept other success criteria. International Journal of Project Management, 17(6), 337–342.

International Project Management Association (IPMA). (2006). IPMA Competence Baseline.Version 3.0. Nijkerk, The Netherlands: International Project Management Association.

Review Questions