23 Introduction to Lean Construction

Learning Objectives

After reading this chapter, you should be able to:

- Define ‘lean construction’

- Understand the types of waste on construction projects

- Be able to list various methods used on projects to increase value and reduce waste

- Describe the Last Planner System™

- Understand the process of developing a Lean Deployment Plan for a project

Defining Lean Construction

Leanis a culture of respect and continuous improvement aimed at creating more value for the customer while identifying and eliminating waste (LCI 2022a).

Lean Construction is a project delivery process that uses Lean methods of maximizing stakeholder value while reducing waste by emphasizing collaboration between teams on a project. The goal of Lean construction is to increase productivity, profits, and innovation in the industry (LCI 2022b).

Video 1 below discusses the meaning of Lean Construction from the Lean Construction Institute (https://staging-leanconstruction.kinsta.cloud/lean-topics/lean-construction/).

Video 1: What is Lean Construction? (Source: LCI 2022b at https://leanconstruction.org/lean-topics/lean-construction/)

Lean concepts originated from the Toyota Production System, and many earlier references to lean concepts reflect upon Japanese terminologies, such as ‘muda’ for waste or ‘kaizen’ for continuous improvement (see https://txm.com/place-japanese-lean-jargon-place-japan/ for additional examples).

The 6 Tenets of Lean

The Lean Construction Institute (LCI) has identified six core tenets of Lean (see Figure 1). It is important to note that the foundation is ‘Respect for People’. Without this respect, it is difficult to adopt a lean approach on projects or within organizations.

It is important to note that the foundational tenet within Lean Construction is ‘Respect for People’. Without this respect, it is not possible to successfully achieve the other five tenets. This foundation principle is embedded throughout lean projects.

8 Wastes on Construction Projects (Muda)

One of the core tenets of lean is to eliminate waste (or muda). To do so, one must first be able to identify waste. There are many sources of waste on a construction project. Obvious waste can include the need to redo work that is not acceptable or wasted time due to not having the proper materials to complete a task. But other wastes are less obvious, such as not leveraging the full talents of the team members.

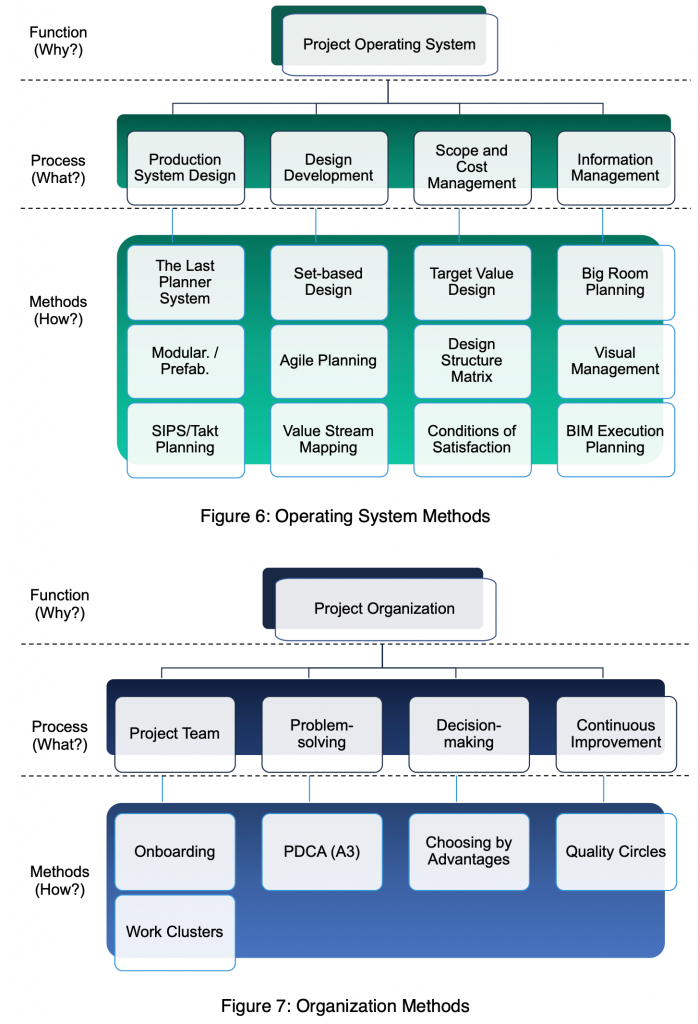

Lean Construction Methods

Many methods can be applied to achieve the Lean principles. These can include simple methods, such as completing each meeting with a plus-delta activity, focused on identifying what went well and what could be improved in future meetings to enable continuous improvement. Or they can include more complex, comprehensive methods such as target value design which focuses on developing a design that meets the overall project budget through frequent interactions of design and construction cost estimating.

The Last Planner System

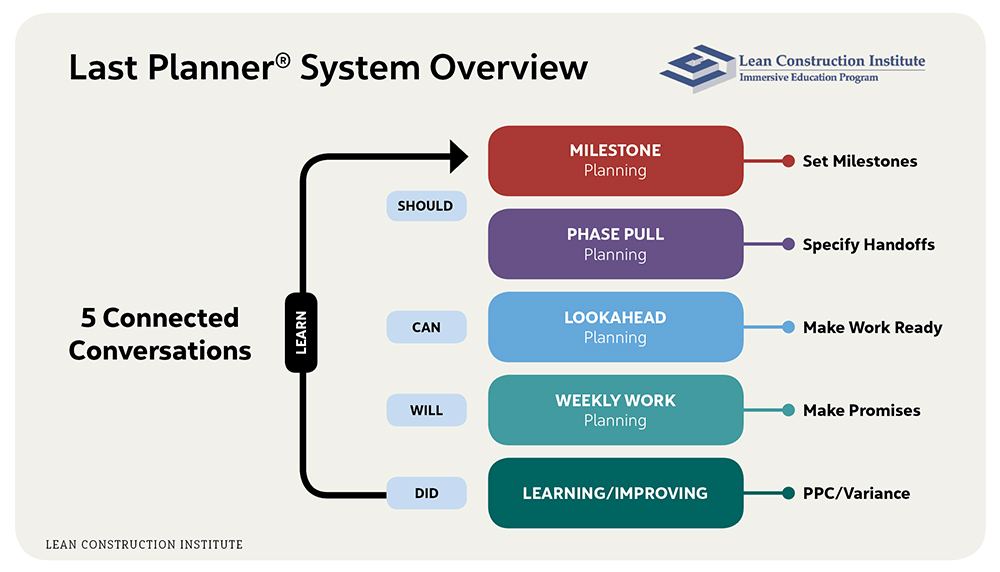

The most popular lean construction system is the Last Planner System. The Last Planner System is composed of several integrated lean methods.

Lean Deployment Planning

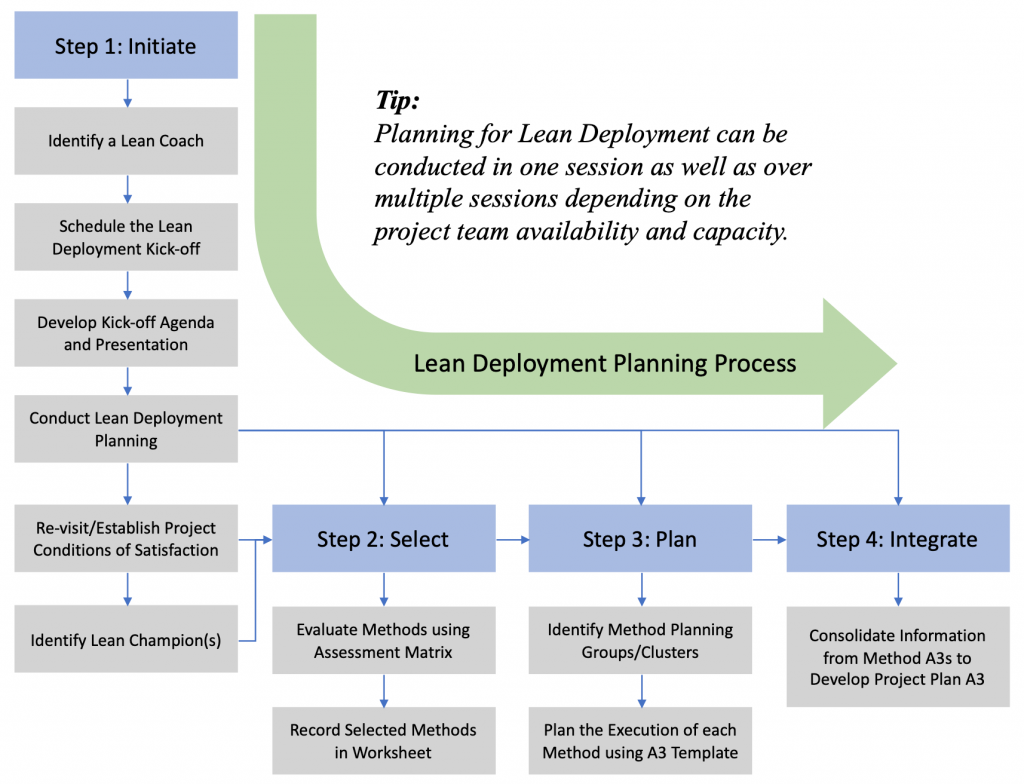

Lean Deployment Planning focuses on developing a detailed implementation plan for lean on a project during the earlier stages of the project. Ideally, the team members will get together and collectively develop and document this lean deployment plan.

The Lean Construction Institute through a Penn State research team developed a guide to support creating a Lean Deployment Plan. This Lean Deployment Planning Guide walks a project team through a structured process to design and document their plan. The main steps in this process are to initiate the plan development, select the lean methods to be adopted, plan each method, and integrate the individual method plans and metrics into a comprehensive plan (see Figure 5).

Enterprise Adoption of Lean

It is important to note that lean principles, or lean transformation, can be applied at both a project or an organizational level. The Lean Enterprise Institute has developed a lean transformation framework to conceptualize the important considerations when transforming an enterprise or company (see Video 2).

Video 2: The Lean Transformation Framework by the Lean Enterprise Institute

Review Questions

References

Lean Construction Institute. (2022a). What is Lean?, available at https://leanconstruction.org/lean-topics/what-is-lean/, accessed on December 27, 2022.

Lean Construction Institute. (2022b). What is Lean Construction?, available at https://leanconstruction.org/lean-topics/lean-construction/ accessed on December 27, 2022.

Messner, J., Leicht, R., and Bhawani, S. (2019). The Lean Deployment Planning Guide, Version 1.1, available at https://leanconstruction.org/download-page/lean-deployment-planning-guide/

a culture of respect and continuous improvement aimed at creating more value for the customer while identifying and eliminating waste.

a project delivery process that uses Lean methods of maximizing stakeholder value while reducing waste by emphasizing collaboration between teams on a project. The goal of Lean construction is to increase productivity, profits, and innovation in the industry.