4 Project Delivery Methods

Learning Objectives

After reading this chapter, you should be able to:

- Understand the different aspects included in typical project delivery methods

- Define the impact of various organizational structures on delivering a project

- Describe the different payment methods for contractors on a project

- Explain the types of award methods for selecting team members

- Draw an organizational chart for multiple types of organizational structures

- Describe the meaning of ‘partnering’ and ‘fast-tracking’

Project owners use many different approaches to procure the services needed to design and build a facility. Some facilities are quite easy to build, relatively speaking, such as a simple single-family detached house. This type of building may allow an owner to simply hire one entity to both design and build their building. Others are very complex facilities, such as a large industrial facility or a complex hospital or lab. These can engage many organizations. But no matter how complex, the owner, and other project participants, have many decisions to make related to developing their strategy to acquire the services that they need to deliver their facility. These decisions can be developed into an overall Project Delivery approach.

It is important to note that prior to developing the overall project delivery strategy, an owner must clearly define the scope boundaries of a project. For example, sometimes an owner will seek to build multiple buildings on a large parcel. If so, then the owner will need to decide whether to make each individual building a project, or group the buildings into a single project. For office buildings, the owner may need to decide whether to have the core and shell be one project, and the tenant fit-out is a second project or multiple additional projects. These decisions define the extent of the project scope.

Primary Elements of a Project Delivery Strategy:

Several core project delivery decisions that will influence the project include:

- Defining the organizational structure;

- Defining the contracting method(s) (payment method(s)); and

- Defining the award method(s).

These decisions are certainly related to each other, and we will explore some typical combinations.

Project Organizational Structure

The project organizational structure focuses on the approach that is used to organize the team members. This structure can have a significant impact on team responsibilities, roles, level of risk, and interactions. The organizational structure is defined by the contracts that are put into place by the team members. For example, in a Design-Bid-Build approach, the Owner will sign separate contracts (or agreements) with a Designer and a General Contractor. Each contract will clearly define the scope of services to be performed by each entity. The 7 organizational structures that may be used include:

- Design-Bid-Build with a GC (also known as Traditional Delivery)

- Design-Bid-Build with multiple prime contractors

- CM Agent with GC

- CM Agent with multiple prime contractors

- CM at Risk

- Design-Build

- Integrated Project Delivery (IPD)

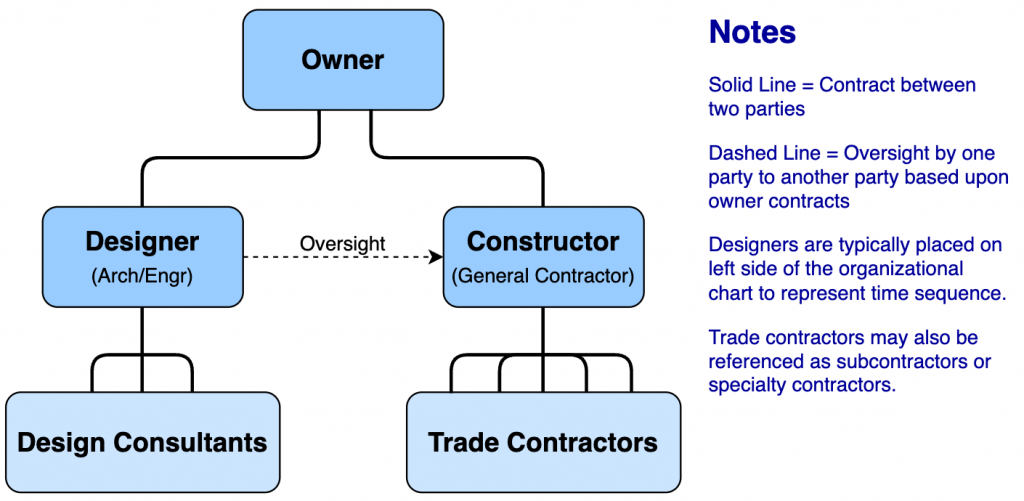

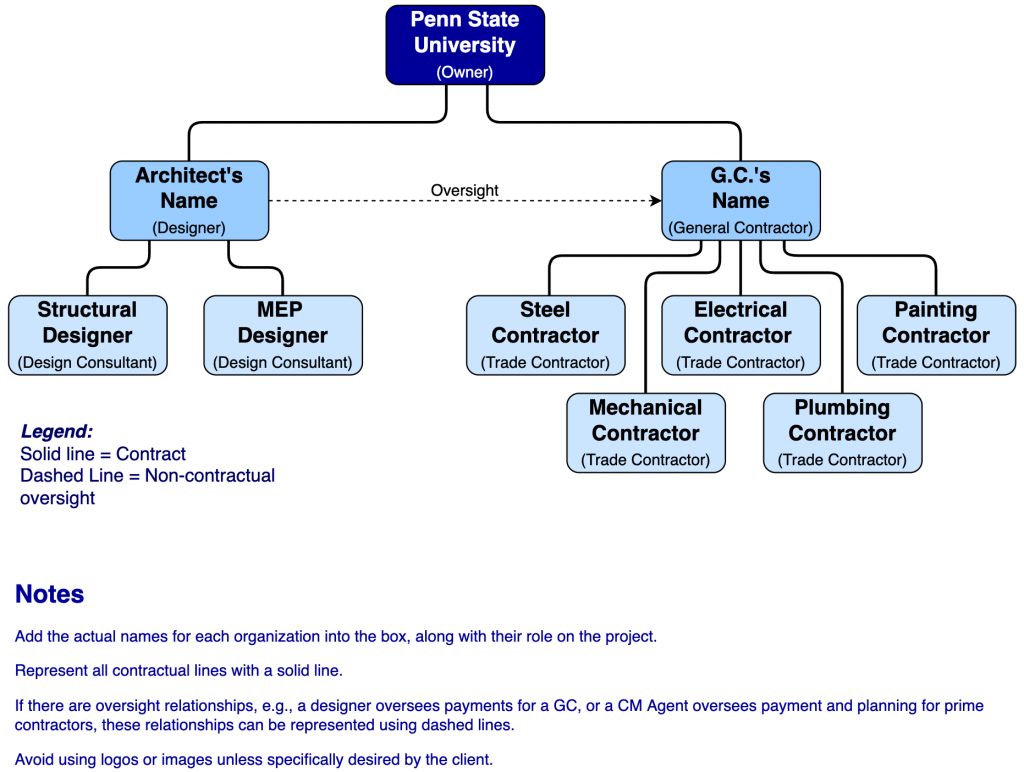

Design – Bid – Build with a General Contractor

Often referred to as ‘traditional’ delivery, the design-bid-build with a General Contractor (DBB with GC) remains quite commonplace. In this approach, an owner will initially hire a design firm (typically an Architect for a commercial building project). The designer will fully develop the design documents, through the completion of the Construction Documents phase (100% complete), and then the Owner will release the documents for the bid for a single organization (the General Contractor) to perform all scopes of work in the project. The potential general contractors will provide a bid to the owner. Typically, the owner will then select the lowest bidder, although they may use a different award method (see later in the chapter). The owner will then enter into a contract with the Constructor (a General Contractor) to construct the building. A diagram showing the project organizational structure for DBB with GC is shown in Figure 1. This figure shows solid lines for contracts. It includes a dashed line between the design and contractor to illustrate the influence that the Designer has on the Constructor based on the owner’s contracts. For example, the architect will typically review the constructor’s payment request prior to payment. The architect will also typically review the completed work of the constructor to ensure that it meets the defined quality in the contract. If it does not, the architect will develop a deficiency list (frequently referred to as a punchiest) that will need to be addressed prior to acceptance of the GC’s work by the owner. It is critical to understand that the architect will have influence over the GC, but the Architect will not hold any contract with the GC. This becomes very important if there is a claim on the project since claims will typically only follow contract relationships.

The DBB with General Contractor (GC) approach is a common method for public procurement. It has been viewed by many in the public sector as an approach to provide fair competition for entities who competitively bid on the project, and a clear selection criterion (low bid) when delivered with a competitive bid award method. There are also many other entities that use this approach.

Some benefits of DBB with GC are:

- The GC knows the full scope of the project, as defined in the construction documents, prior to providing a bid for the work;

- The Owner can select a design firm independent of their ability to construct a project;

- The Owner has clear criteria to select the constructor (low bid) since the Design-Bid-Build approach almost always aligns with a low bid selection process. The bidders may need to prequalify to bid on the project.

- The Owner may get a lower price if the scope is well defined and there is strong competition for bidding on the project.

But there are some significant challenges with this approach. These include:

- There is no opportunity for a contractor to provide input into the design process, which can limit the potential for gaining early cost estimates, constructability feedback, and feedback to improve opportunities for modularization or prefabrication.

- It is not always clear that the low bidder will yield the lowest final cost since there tend to be higher rates of change orders given this approach.

- This is a slow delivery approach since the design must be 100% complete prior to putting the documents out to bid.

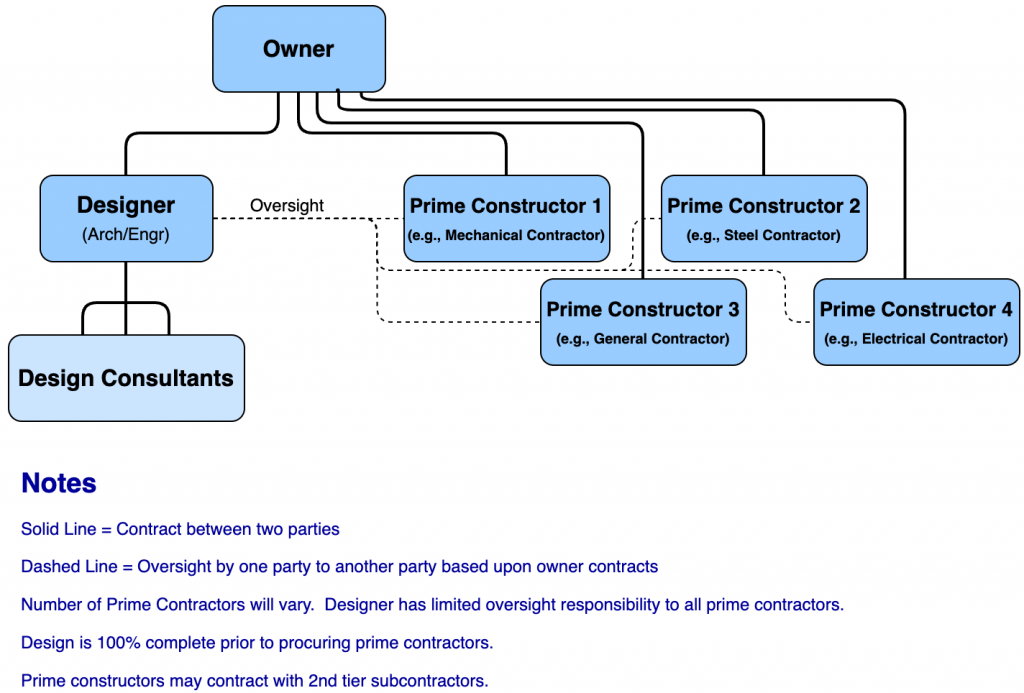

Design – Bid – Build with Multiple Prime Constructors

One variation of Design-Bid-Build is for the owner to separate the scope of work into multiple trade or scope packages, and then independently bid each package. This yields a similar structure to DBB with GC, but instead of a single GC, there are multiple trade contractors (see Figure 2). This approach carries many of the same advantages and disadvantages as the DBB with GC. One envisioned additional advantage of this approach is that the Owner will not pay overhead costs for a GC to manage the other prime trade contractors. But, one additional disadvantage is that the Owner will now take on additional responsibility in the management of the various prime contracts. This will require additional coordination and administrative effort for the Owner. For less experienced owners, this additional burden can be quite challenging.

Note that this delivery approach is sometimes required by public procurement regulations in a small number of public owners. One public owner that sometimes requires DBB with Multiple Prime is the Commonwealth of Pennsylvania. For state-funded projects in Pennsylvania, there is a minimum requirement per the Separations Act, 71 P.S. §1618 that the owner use a multiple-prime delivery system with each prime construction contract being competitively bid. The minimum number of prime contractors includes 1) general construction, 2) electrical, 3) plumbing, and 4) heating and air conditioning. For this reason, there are a number of schools and other public projects funded by the Commonwealth of Pennsylvania that must be delivered with this approach.

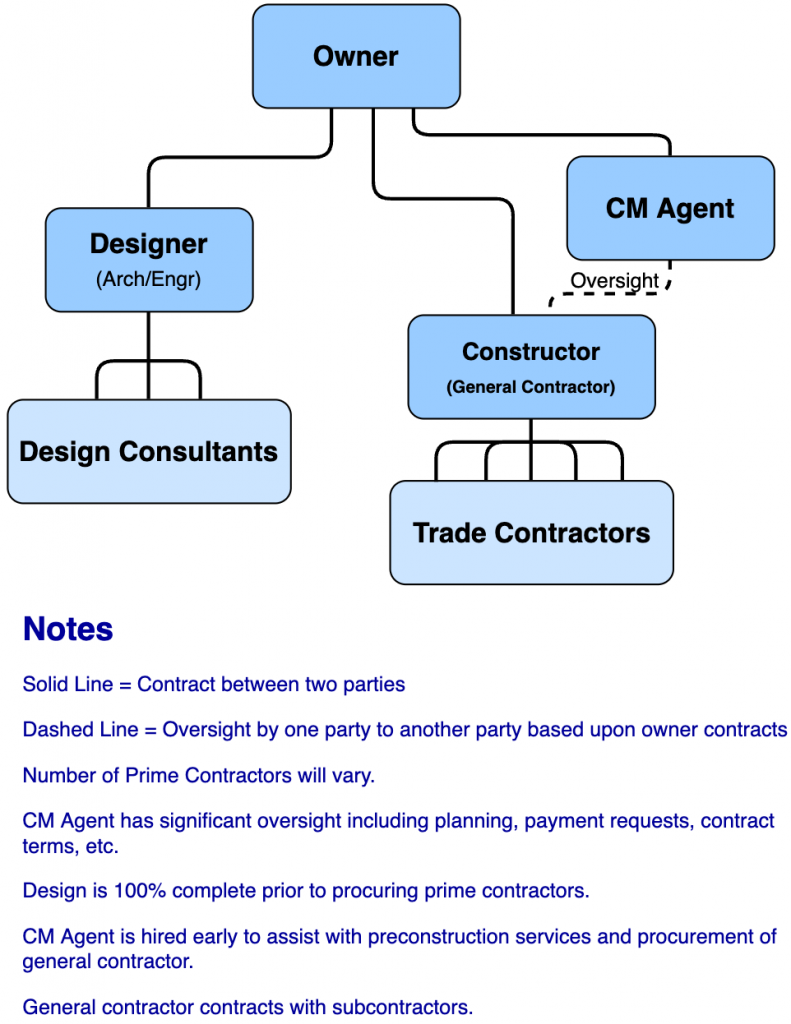

Construction Management Agent with General Contractor

The Design-Bid-Build delivery approach requires significant interactions by the owner of the project during the delivery process. To assist with the tasks that need to be completed by an owner, and provide significant expertise to deliver a project effectively, some owners will deliver a project with a Construction Management Agency. This CM Agent will be a paid entity that helps an owner perform their required activities in the delivery process, including the oversight of procurement of entities throughout the project, administering of contracts, planning and coordinating construction activities, approving payment requisitions, overseeing overall project safety and quality, providing constructability input into the design, along with many other tasks. This CM Agent arrangement is particularly valuable for complex projects, or for projects that have an owner who may not have the resources or expertise to manage the project effectively.

The CM Agent will review the operations of the General Contractor (GC), and report important information to the Owner. It is important to note that the CM Agent has no direct contract with the General Contractor. This limits the liability and responsibility between the General Contractor and CM Agent. If the GC were to file a claim, they would need to do so with the Owner, since claims will follow the contractual relationships. In some instances, the CM Agent with a GC arrangement may pose a scenario where one market competitor will be overseeing another market competitor, which can be a challenging dynamic.

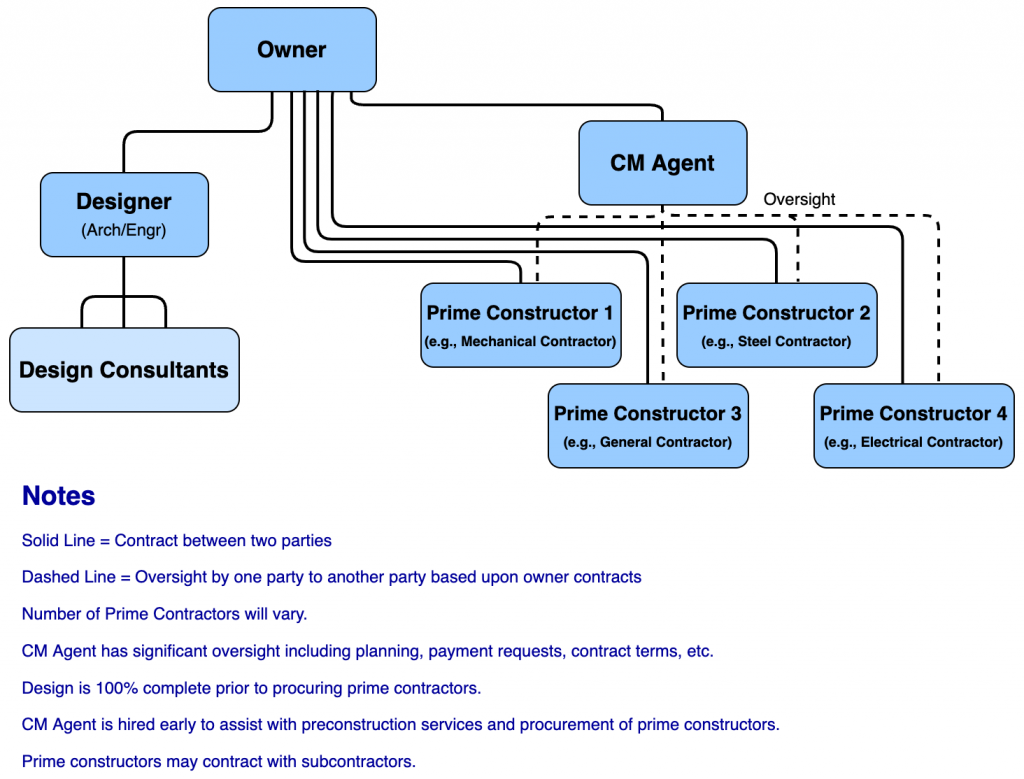

Construction Management Agent with Multiple Prime Contractors

This approach places a CM Agent into the organizational structure of the DBB with Multiple Prime Contractors. This can be quite helpful in assisting with some of the challenges inherent in the DBB with Multiple Primes. For example, the CM Agent can be hired early in the process, and then provide construction input into the design, and monitor cost estimates throughout the design phases. The CM Agent can also organize and prepare the different bid documents to hire multiple trade contractors. Finally, the CM Agent can supplement the owner’s resources to coordinate the contractors and administer their contracts. This is a common method to use when there are procurement regulations that require DBB with Multiple Prime Contractors.

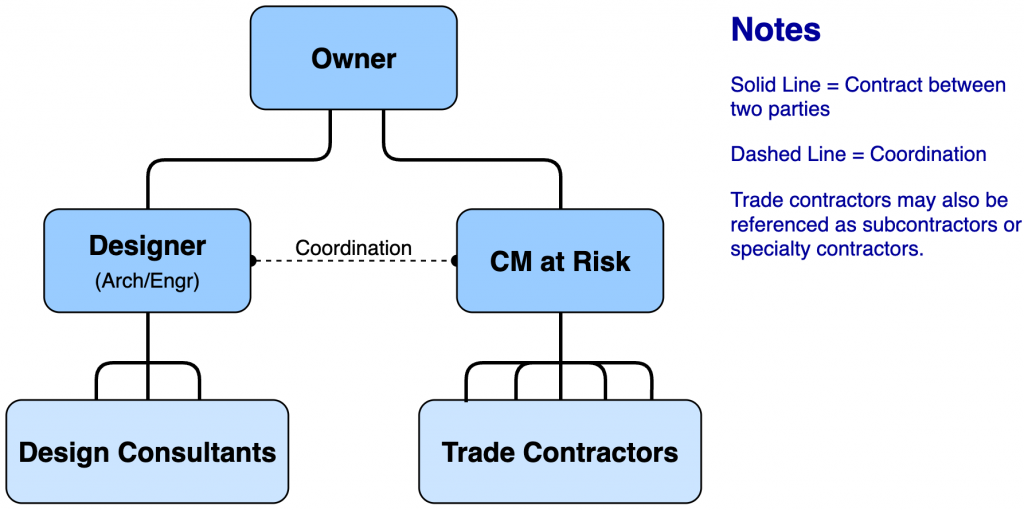

Construction Management at Risk

Construction Management at Risk is an approach where the owner will hire a designer to develop the facility design, and sometimes, usually early in the design process, they will hire a construction management company to perform both construction services during design along with managing the overall construction of the facility. The services that they will provide during design will include reviewing the design for constructability, developing bid packages for the hiring of trades, identifying and prequalifying trades, and performing cost estimates. A CM at Risk will eventually Guarantee a price for the project. This is frequently performed through a Cost + Fee with a Guaranteed Maximum Price (GMP) contract, but it could also be through a lump sum contract (see details later in this chapter). The CM is at risk since they directly hold all contracts with the trade contractors, in contrast to the CM Agency where the Owner holds the contracts with the trade contractors. A CM at Risk is a good delivery method to allow an owner to hire a preferred designer, still have some checks and balances in the system, yet also gain benefits from early constructor involvement. This approach allows for collaboration between the design and CM, although this collaboration is not always as close as some of the more integrated approaches of Design-Build or IPD.

This delivery method may also be referenced by different names. In particular, within the highway construction sector, this delivery method is known as Construction Management/General Constructor (or CMGC).

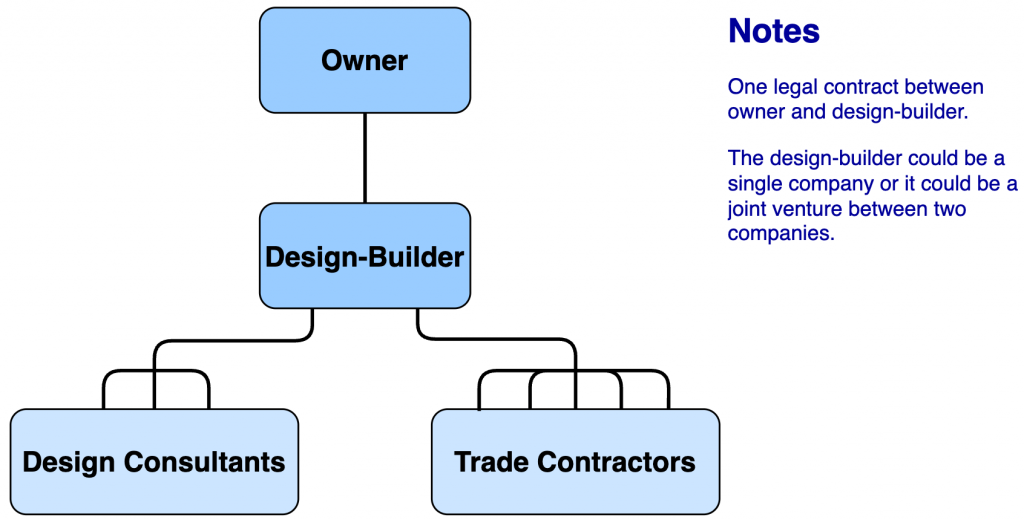

Design-Build

Design-Build (DB) is focused on having a single entity perform both the design and construction of a project. Within the Design-Build approach, an Owner will hire a single entity after developing a program for the project. The program will outline the requirements for the project, e.g., space requirements and other designed outcomes. The design-build entity will then perform the design of the facility and be responsible for construction.

A core and unique aspect of design-build is the single contract between the Owner and the Design-Build entity. The design-build entity will be a legal entity but could take many different forms. For example, it could be an integrated design-build company, or a single-purpose joint venture developed between a design firm and a construction firm to pursue a project. In many instances, the design-build entity is a construction company, which then subcontracts the design tasks to a designer. Or in some cases, the design-build entity is a designer, who subcontracts construction to a construction company, although this is rare.

This single entity approach for both design and construction allows for many potential benefits. It allows for a very tight integration of construction means and methods with the design of the facility. It also allows the team to develop accurate cost estimates throughout the early design phases, and identify approaches to save costs and provide added value within the construction process.

While there are many benefits to the integration that can occur in Design-Build, there are also some potentially negative aspects. A primary concern that may be expressed within design-build is that the owner may not have an independent advocate within the checks and balances of having both a design and construction contract. In a more traditional approach, the design firm frequently has some oversight role of the contractor, and the contractor has an opportunity to share their opinions regarding the designer with the owner. In a design-build project, the owner does not have a second opinion in the same manner, and therefore, may not receive the same feedback. The owner may also have concerns that the design-build firm is trying to maximize its success to the detriment of the project. While these are valid concerns that must be appropriately managed through project control systems and hiring a high-quality team, many owners find design-build to be a very effective method to deliver a project.

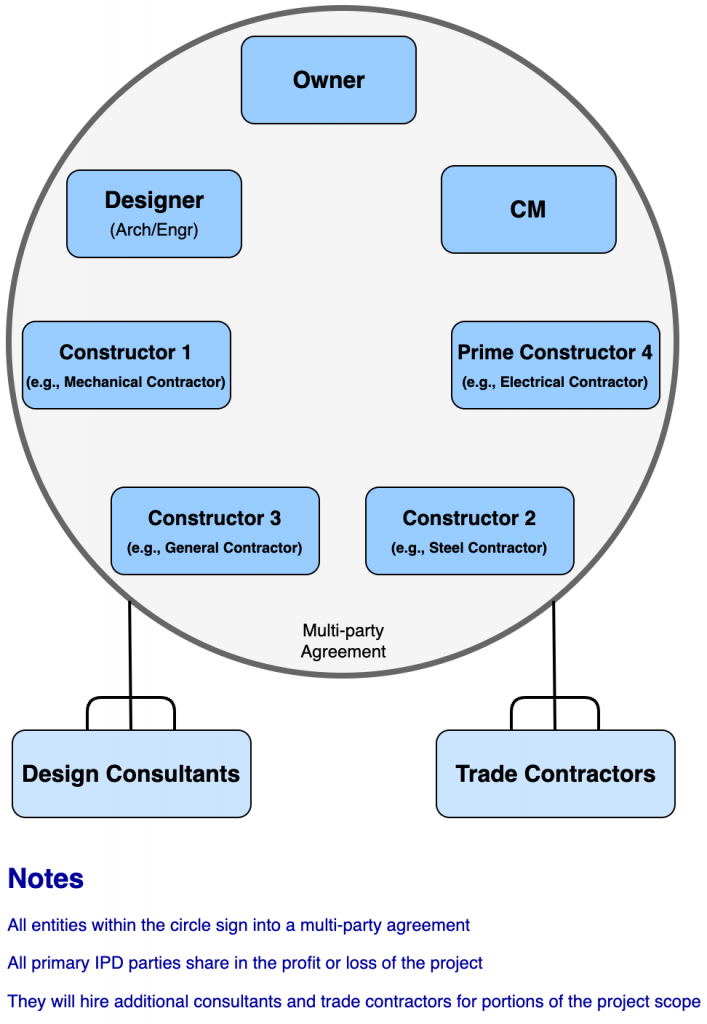

Integrated Project Delivery (IPD)

Integrate Project Delivery (IPD) is a newer contracting format where the entire team is engaged in the successful delivery of the project, including the owner, designer(s), and contractor(s) through a very integrated, shared risk/reward approach. Projects delivered using the Integrated Project Delivery organizational structure have core members enter into an Integrated Form of Agreement (IFoA). This IFoA is a single contract for the project that is signed by all core team members, including the owner. This is a very unique structure that is unlike other delivery methods. Typically, all core members will share the risks of designing and delivering the project, along with the potential financial rewards if the project is delivered on or below the target budget while meeting the other project goals.

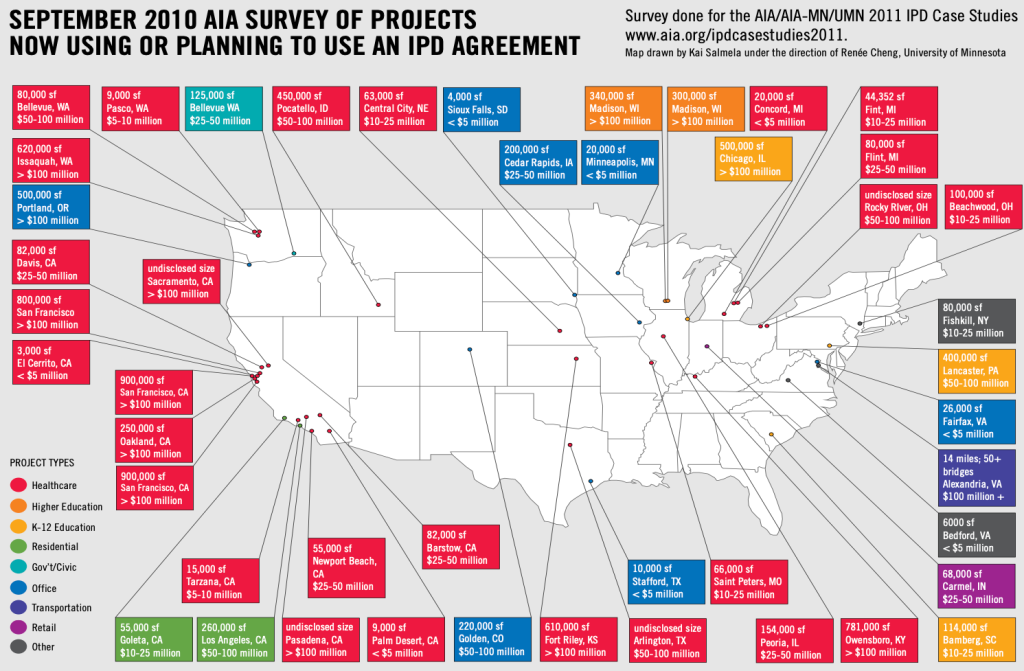

Figure 4-8 shows a survey of IPD projects that were performed in 2010. While adoption has continued to increase since 2010, there are still very few projects that are delivered using the IPD approach.

There are typically many unique management aspects associated with IPD projects. For example, the integrated team will frequently form a cluster group at the beginning of the project to manage particular scopes of work or focused issues. They will frequently set up a ‘big room’ to collocate the team to a common location to better integrate the design and construction team members. During design, the team will frequently use target value design approaches to ensure that they are designing the project to budget. They will also frequently leverage lean construction methods, including pull planning and the Last Planner System, to manage production. These different systems will be discussed in more detail in a later chapter. A good discussion of the IPD delivery approach is included in Integrated Project Delivery: A Guide by AIA (2007).

Contracting Method

There are many items covered within a contract. One of the most significant items in the contract in relation to the delivery approach is the payment terms, which define how payments are made from one party to another. Common payment terms include lump sum, cost plus a fee, cost plus a fee with a Guaranteed Maximum Price (GMP), or unit cost.

Lump-Sum (or Stipulated Sum)

In a lump sum payment approach, the owner will pay a fixed amount to the contractor for the work performed. This amount is paid on a periodic basis, typically each month. For the prime contractor(s), a Lump Sum arrangement typically corresponds with a traditional, design-bid-build delivery approach, although it can be used with other organizational structures. Within a Lump Sum contract, the contractor will either make a profit, if they can construct the building for less than the lump sum value, or they will lose money if they can not construct the building for the value. This transfers a significant amount of the risk for financial performance to the constructor. If the contract scope is changed or there are errors in the construction documents that increase the cost of construction, the constructor can file for a change order to increase the lump sum value. A lump sum payment arrangement may also be referenced as a stipulated sum arrangement. It is also important to note that many owner-designer contracts have a stipulated sum (or lump sum) amount. This value may be estimated as a percentage of the total project costs, but the value is frequently incorporated into the contract as a stipulated sum. The design firm may also have additional compensation amounts, e.g., reimbursement for travel to the site or meetings.

Cost Plus a Fee

The Cost Plus a Fee approach leaves the final contract value open. It is a contractual arrangement where the owner (or a separate prime contractor) pays for all costs of performing the work, including labor, materials, equipment, and potentially other costs, plus an agreed-to fee. The fee may be a lump sum fee or it may be a percentage of the cost of work. A Cost Plus a Fee arrangement is typical for projects where the full scope is not well defined, and the owner wishes to start the work. This contracting method carries a significantly lower risk to the contractor. The contractor will need to account for all of their costs, and share these details with the owner. This approach is frequently referred to as Open Book since the contractor will share their accounting with the owner, and the owner typically has the right to perform a full audit of the books.

Cost + Fee with Guaranteed Maximum Price (GMP)

To overcome one of the challenges with Cost + Fee contracts, many Owner – Construction Manager (or some others) contracts have a Cost + Fee with GMP. In this approach, an owner will pay all the costs of work along with a fee to a maximum agreed-to value. If the contractor exceeds the value of the GMP, then they will only receive the GMP value. If they spend less than the GMP value, then there are savings. Cost + Fee with GMP contracts will define what happens with savings. In many instances, they are shared between the owner and the contractor at some percentage, e.g., 50-50 or 75-25. In other instances, all the savings may go to the owner. With the Cost + Fee contract, the contractor will provide invoices accounting for all the costs that they have incurred. This is an Open Book approach since the owner can audit the accounting on the project.

Unit Price

For some scopes of work, although not typically an entire project, an owner or contractor will pay a supplier or subcontractor a unit price amount for a scope of work. For example, the contractor may pay for concrete by a cubic yard of a specific mix design, or an excavation subcontractor may be paid by the cubic yard of excavated material. A benefit of the unit price payment method is that you can set up a project with a clear cost per unit, while not necessarily knowing the full scope of the work. A downside for the contracting entity is that there is no guaranteed final cost since it is dependent on the quantity, and there must be a quality method to document the actual quantity performed.

Award Method

When one party would like to hire another party to perform a service or provide a product, the party must decide how they will select the other party. There are many different approaches to selecting the method that they will use to award the contract. For design and construction contracts, these methods can be broadly categorized into a) competitive bid, b) prequalified competitive bid, c) best value selection, and d) negotiated selection.

Competitive Bid

One traditional method to select a contractor is to select the lowest cost contractor in a competitively bid arrangement. In this approach, all contractors will submit a bid, and the Owner, or selecting entity, will review the bids and select the lowest cost qualified bidder. This approach is very commonly used for public projects, along with many private projects.

Prequalified Competitive Bid

One challenge of an open competitive bid is that the owner may select a contractor who technically fits the qualifications, but that the owner does not feel has more advanced qualifications. In some instances, an owner will proceed with a 2 step process. They will first prequalify a subset of the potential bidders, through the review of a qualification submission for each potential bidder. Then, they will ask each of the prequalified bidders to submit a bid for the cost of the project, and they will select the lowest cost bidder from the prequalified contractors.

Best Value Selection

Another approach to selecting a contractor is to develop a best-value selection process. In this approach, the owner will identify the criteria that they value, and develop an approach to weigh each of the criteria. These criteria may include the quality of the team, experience on a similar project, plan for approaching the project, and other criteria. They will also include cost as a factor, but not as the only selection factor. Once these criteria are identified, then the owner will review the submissions from potential contractors and rate each of the criteria. The final item to be reviewed and weighted will be the cost. The selection will occur based upon the contractor who rates the highest in the combined weighted equation. This approach can yield the selection of a contractor who aligns more closely with the values of the project.

Negotiated Selection

A final approach to selecting a contractor is to identify an entity (or entities) that you would like to hire, and then directly negotiate a mutually acceptable agreement with the entity. This has the benefit of being able to select the entity directly, but this may not be allowed in many public organizations due to a lack of competitive selection. There are exceptions in public procurement laws, but this is typically not allowed.

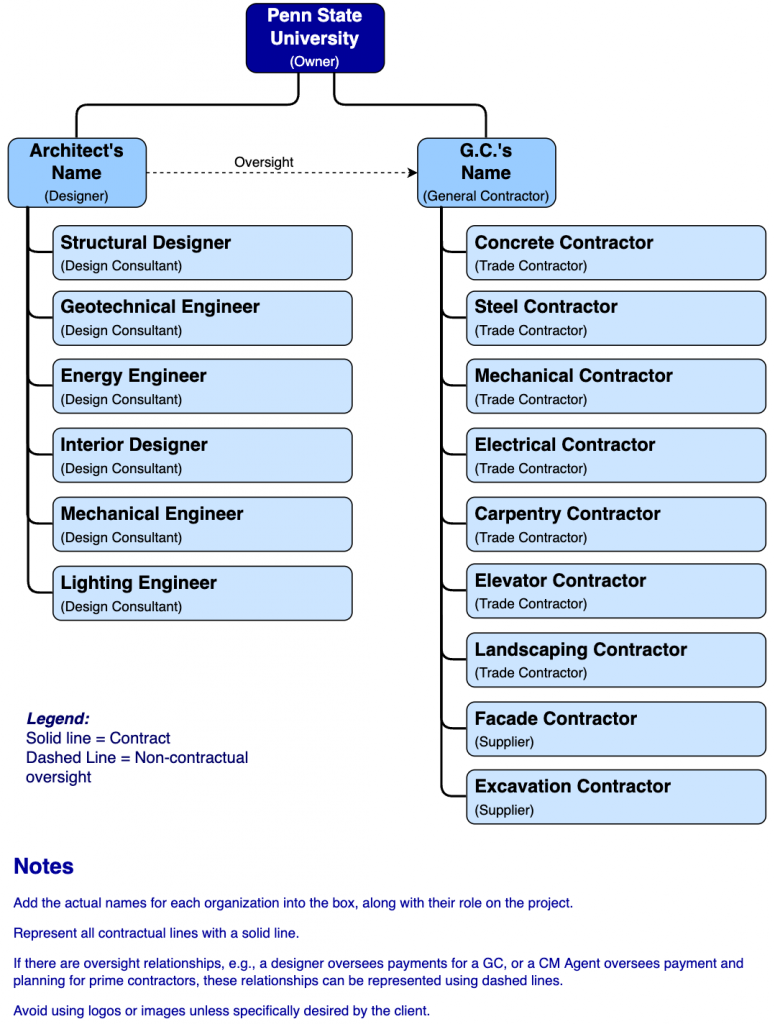

Project Organizational Charts

It is very common to draw a project organizational chart (sometimes simply called an ‘org’ chart) that identifies all primary parties on a project. These charts also show the contractual relationships between the parties, indicated by lines in the diagram. Note that project organizational charts focus on the relationships between the organizations on the project, unlike an organizational chart for personnel within a single organization.

Project organizational charts can sometimes be quite graphic, with companies using their logos or other symbols, or they may simply show the entities and their relationships. In the examples that follow, we will keep the project organizational charts simple, and simply show the core attributes of the delivery strategy. Figure 9 shows a relatively simple sample organizational chart for a design-bid-build structure. Figure 10 includes a more comprehensive organizational chart that you would see for larger projects with more trade contractors and more design consultants. Also, note that each sample has a legend that you would want to include with an organizational chart. In addition to showing the contract lines, you could also include the contract type on these lines, e.g., LS for a lump sum, or Cost+ for cost plus a fee. These are not included in the samples below.

When drawing a project organizational chart, it is typical to have the owner at the top of the chart. The owner initiates all of the prime contracts on the project. By saying ‘prime’ contracts, that means that an entity is directly contracted with the owner. As we proceed vertically through the project organizational chart, the levels of contracts are sometimes referenced by their relationship to the prime contractors. For example, a party that contracts with a prime contractor is sometimes referenced as a ‘subcontract’, or sometimes (but not often) a first-tier subcontractor. This means that the subcontracted party has a direct contract with a prime contractor. Then, if a subcontractor initiates a separate contract with a trade contractor, they may be referred to as a ‘second-tier subcontractor’. For example, an owner may contract with a general contractor as a prime contractor. Then, the general contractor may contract with a mechanical specialty trade contractor via a subcontract. The mechanical trade would be a subcontractor. The mechanical specialty trade may then contract with a controls contractor who would be a second-tier subcontractor. The sample project organizational charts in the figures above only have prime and subcontractor parties, they do not include any second-tier subcontractors.

Payments, roles, and responsibilities follow these contract lines. In the above example, the owner would pay the prime contractor, the prime constructor will then pay the subcontractors, and the subcontractors will then pay the second-tier subcontractors.

It is helpful to use a graphics program when developing a project organizational chart. The charts used in this book were developed in diagrams.net. This is a free, open-source software application. You can either download the application locally or you can use a browser-based version of the application at https://diagrams.net The sample organizational charts in this chapter can be downloaded as a template document at this link. There are multiple pages in this file that you can easily use to select the appropriate organizational structure and modify the template organizational chart as needed.

Related Topics

There are several related topics that some may consider within the project delivery methods area. The following items focused on partnering and fast-tracking are NOT project delivery methods, but instead, they are related to the delivery of projects and the relationships of the project team members.

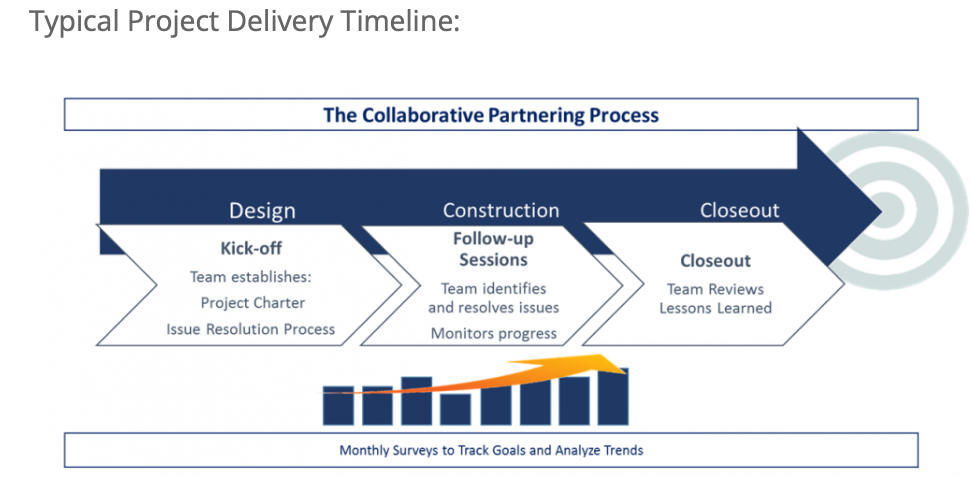

Partnering

The Construction Industry Institute (CII) (1996) defined partnering as “a long-term commitment between two or more organizations as in an alliance or it may be applied to a shorter period of time such as the duration of a project. The purpose of partnering is to achieve specific business objectives by maximizing the effectiveness of each participant’s resources.” International Partnering Institute (IPA) defined “construction partnering as a structured process that brings a design and construction team together regularly throughout the life of a project. Partnering provides a space for communication, improved strategy, and issue resolution.”

The partnering process, which may be contractual or non-contractual, puts in place a series of collaboration approaches aimed at improving the relationships between project participants, regardless of the formal delivery method used. For example, on projects with a formal partnering agreement, the partnering program will typically work to develop a formal partnering charter for the project, focused on defining how the team seeks to work together and how they will ensure valuable collaboration. Items that may be included in a comprehensive partnering program include (IPA 2022):

- Partnering Specification: To guide the partnering process and balance the power of everyone in the room

- Charter: Co-created by the team in kick-off session(s) to establish goals and strategies to meet the goals

- Issue Resolution Process: To define an approach to the fair resolution of issues

- Anonymous Surveys: To collect feedback on progress toward goals

- Follow-up Sessions: To update goals, and identify and resolve issues, held at least quarterly

- Lessons Learned Session(s): To capture and learn from experiences

- A neutral professional facilitator: To guide the team through the partnering process

IPA presents the timeline for partnering as shown in Figure 11.

Partnering can be implemented across all delivery methods. Partnering has been shown to aid in timely issue resolution and improved schedule, cost, and quality. It can help the teamwork, together, to focus on core project goals, and to learn from the project experience, as a team.

Fast-Tracking

Simply put, fast-tracking is the overlapping of the design and the construction process. If a project is fast-tracked, then the constructors will start to build some portions of the project, e.g., demolition, excavation, foundation, and possibly structural elements while the designers continue to develop the more detailed design. This fast-tracking will reduce the overall schedule, but it must be managed well to reduce the risks associated with building portions of the project prior to design completion. Fast-tracking can be achieved in many different delivery methods provided the contractors are procured prior to the completion of the design. Therefore, by definition, we can not fast-track in a design-bid-build delivery approach since we need the design to be 100% complete prior to procuring a contractor. But, we can fast-track a project using the CM-at-Risk, CM Agency, Design-Build, and IPD delivery approaches. With the CM approaches, it is important that the CM procure the trades needed to complete the fast-tracked work tasks prior to completion of design.

It is important to note that some people may use the terminology of fast-track and design-build interchangeably, but they are very different topics. Fast-tracking is focused on the parallel scheduling of activities. Design-build is a project delivery approach.

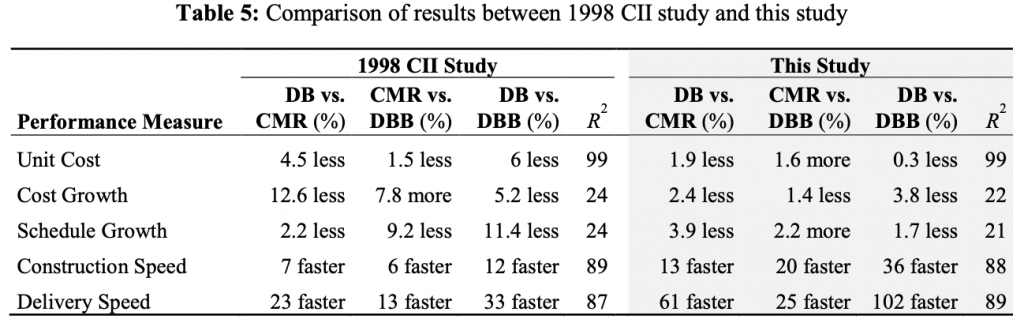

Recent Research

Research has supported the value of more integrative delivery methods. An initial study, performed by Konchar and Sanvido (1995) focused on comparing three broad delivery methods (Design-Bid-Build, CM at Risk, and Design-Build). The study reviewed a significant amount of data related to overall project performance on 351 projects. The conclusions of the study clearly illustrated that Design-Build projects outperformed other delivery methods when comparing cost, schedule, and quality metrics. Specifically, the data indicated that DB has 6% less cost growth than DBB, DB projects were completed 33% faster than DBB, and DB projects had a 10% higher rating for quality than DBB (Konchar and Sanvido, 1998).

More recently, a new dataset of 212 U.S. projects was developed and analyzed (Molenaar and Franz, 2018). In 2018, this data was analyzed to evaluate relative cost, schedule, and quality metrics based on the delivery method adopted for a project. A summary of the quantitative data from the study is shown in Figure 12 (extracted from the study’s final report). Note that the column titled ‘This Study’ is the data analyzed in 2018. This data shows general consistency with the original data from 1998, with Design-Build generally outperforming the CM at Risk, and CM at Risk outperforming the Design-Bid-Build delivery approach.

It is important to note that these study results do not suggest that every project should use a design-build delivery approach. In fact, the study was performed prior to the advent of the more recent Integrated Project Delivery (IPD) approach. A more recent study evaluated the different project delivery attributes that influenced the overall project performance on projects.

Overall, it is clear that well-managed projects that leverage higher levels of integration of team members and budget transparency can yield high levels of success.

Selecting a Project Delivery Method

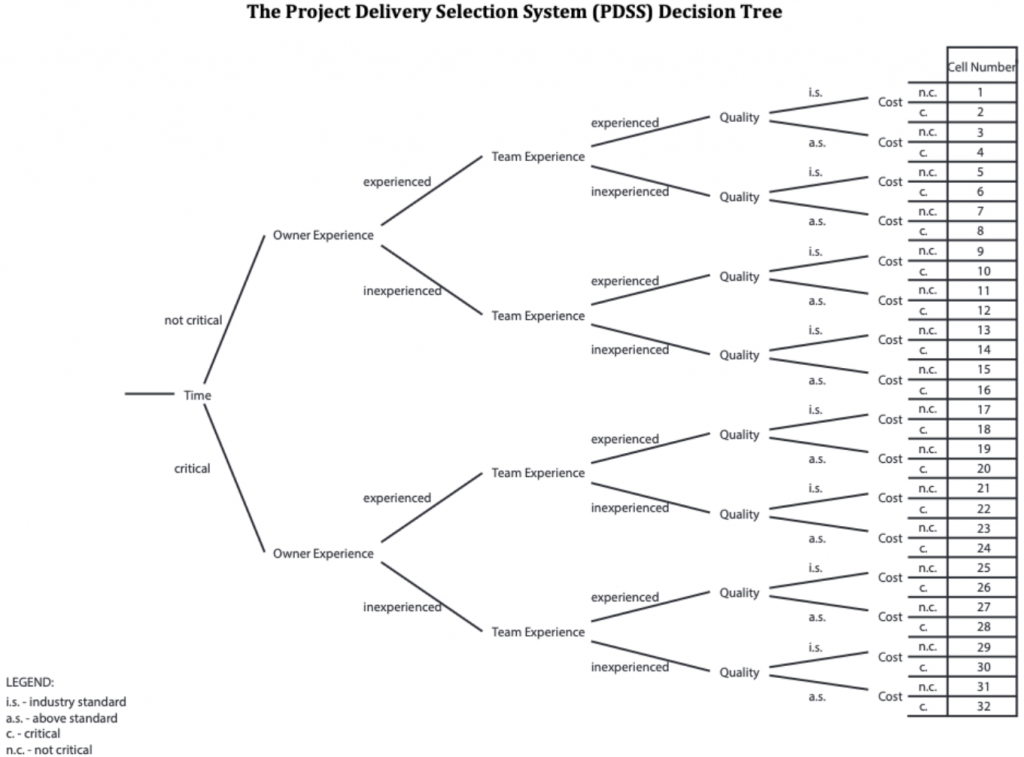

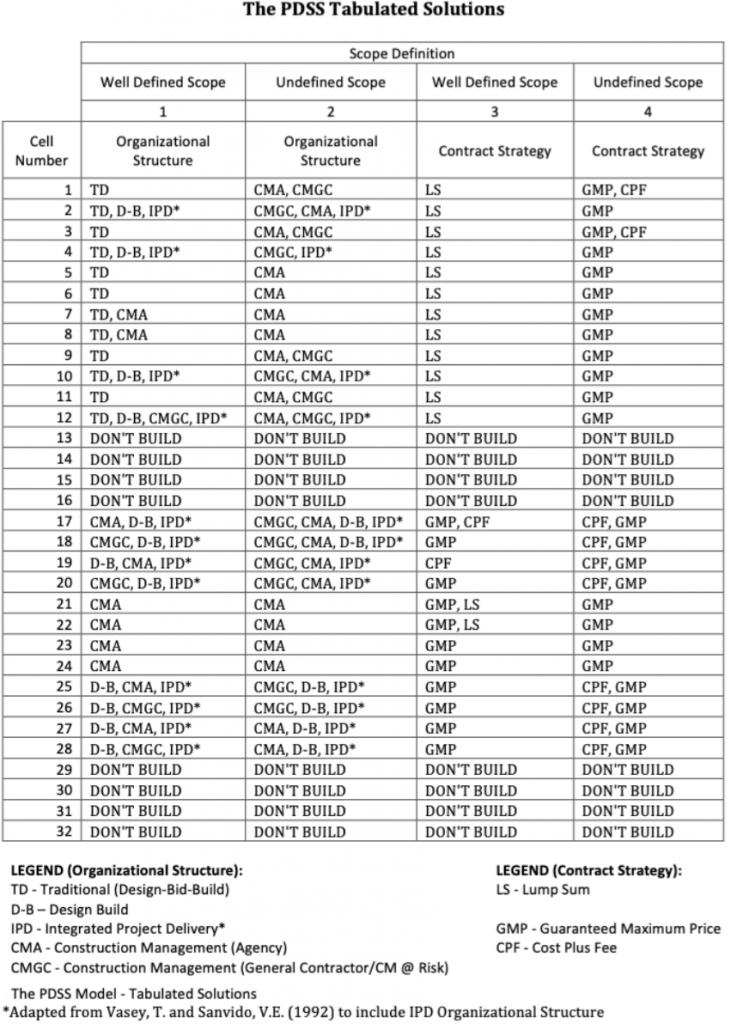

Several guides and tools have been developed to assist owners in the selection of delivery methods. One of the earliest tools developed was the Project Delivery Selection System (PDSS) by Vesay (1991). This simple decision matrix aimed to point an owner to potential delivery approaches that may be most appropriate for their project given a series of project characteristics. In particular, Vesay developed a decision tree using 6 project characteristics which include:

- Scope Definition: Is the scope of the project clearly defined at the time of procurement? (Well Defined/Poorly Defined)

- Time Criticality: Is time critical to achieving project success? (Yes/No)

- Owner Experience Level: Is the owner experienced with managing the delivery of projects? (Yes/No)

- Team (or potential team) Experience Level: Is the team, or the pool of potential team members, experienced with the delivery of similar projects? (Experienced/Inexperienced)

- Quality Level: Is the level of desired quality equivalent to industry standards or above industry standards? (Industry Standard (i.s.) or Above Industry Standards (a.s.))

- Cost Criticality: Is the first cost of the facility critical to success? (Yes/No)

From the answer to these six questions, the PDSS recommends the consideration of one or more potential delivery methods and payment methods. Note that it may point to one suggested method, multiple suggested methods, or suggest that a characteristic be revised prior to proceeding, e.g., more clearly develop the scope prior to proceeding with the project. The decision trees from Vesay (1991) with some additional revisions to include the IPD delivery method are shown in Figure 13 (delivery method) and Figure 14 (payment method). These decision trees are simply meant to guide an owner. Specific project characteristics may limit the potential selection of methods (e.g., a procurement law or restriction). Characteristics may also guide an owner to one method over another, e.g., previous history with a successful team.

A more recent study yielded the Maximizing Success in Integrated Projects: An Owner’s Guide by Leicht et al. (2016). This guide outlines additional items to consider when selecting and managing the delivery of a project. This document highlights the importance of three critical features when delivering projects:

- Early involvement: When possible, get the primary builder, and if possible, the trade contractors involved early in the project design phase;

- Qualifications-based selection: When possible, employ some form of qualifications-based selection, not just low-cost; and

- Cost Transparency: When possible, select a contracting approach that provides cost transparency between the owner and the prime constructor(s). This would include payment methods such as cost plus fee or cost plus fee with a guaranteed maximum price.

Review questions

References:

AIA. (2007). Integrated Project Delivery: A Guide. American Institute of Architects, California Chapter. Available at https://www.aia.org/resources/64146-integrated-project-delivery-a-guide

Leicht, R. M., Molenaar, K. R., Messner, J. I., Franz, B. W., and Esmaeili, B. (2016). Maximizing Success in Integrated Projects: An Owner’s Guide. Version 1.0, January, The Pennsylvania State University. Available at http://bim.psu.edu/delivery

Molenaar, K. and Franz, B. (2018). Revisiting Project Delivery Performance. Final Report, Charles Pankow Foundation, Available at https://www.pankowfoundation.org/our-work/research-grants/project-delivery/integrated/02-18-revisiting-project-delivery-performance/

Vesay, A. (1991). A Project Delivery Selection System. CIC Technical Report 26, The Pennsylvania State University, University Park, PA, Available at https://www.cic.psu.edu/download/TR_026_Vesay_PDSS_1991.pdf.

commitment between two or more organizations for the purpose ofachieving specific business objectives by maximizing the effectiveness of each participant’s resources (CII 1996)