21 Safety Management

Learning Objectives

After reading this chapter, you should be able to:

- Understand that safety can never be compromised for other aspects of a construction project

- Be able to define the importance of safety from an ethical and an economic perspective

- Define effective safety management approaches to improve overall safety on construction projects

- Be able to identify OSHA safety guideline locations and general reporting requirements

- Understand the impact of construction accidents on projects

The Importance of Safety

Safety should be the most critical consideration for all engineers (and others). The Preamble to the current ASCE Code of Ethics starts with:

“Members of The American Society of Civil Engineers conduct themselves with integrity and professionalism, and above all else protect and advance the health, safety, and welfare of the public through the practice of Civil Engineering.

Engineers govern their professional careers on the following fundamental principles:

- create safe, resilient, and sustainable infrastructure;

- treat all persons with respect, dignity, and fairness in a manner that fosters equitable participation without regard to personal identity;

- consider the current and anticipated needs of society; and

- utilize their knowledge and skills to enhance the quality of life for humanity.”

See ASCE Code of Ethics at https://www.asce.org/career-growth/ethics/code-of-ethics

A previous version of the ASCE Code of Ethics stated this even more clearly, with the first Fundamental Canon described as follows:

“1. Engineers shall hold paramount the safety, health and welfare of the public and shall strive to comply with the principles of sustainable development in the performance of their professional duties.” (ASCE 2017)

Safety must always be at the forefront of decision-making, for ethical, legal, and moral reasons. In addition, keeping safety as a priority can also lead to economic and schedule benefits since workers can be more productive when they are safe and they work within an organization that prioritizes safe practices.

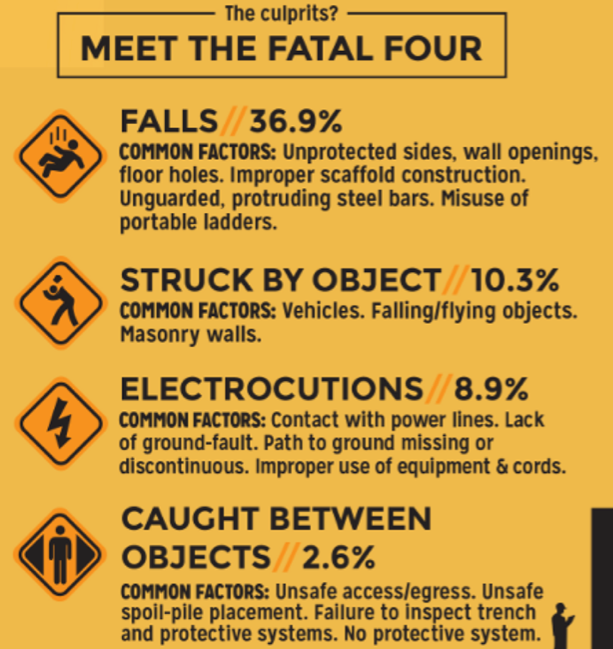

The Top Risks and Accident Types

Planning for Safety

Every project should have a custom project safety plan. This safety plan should include:

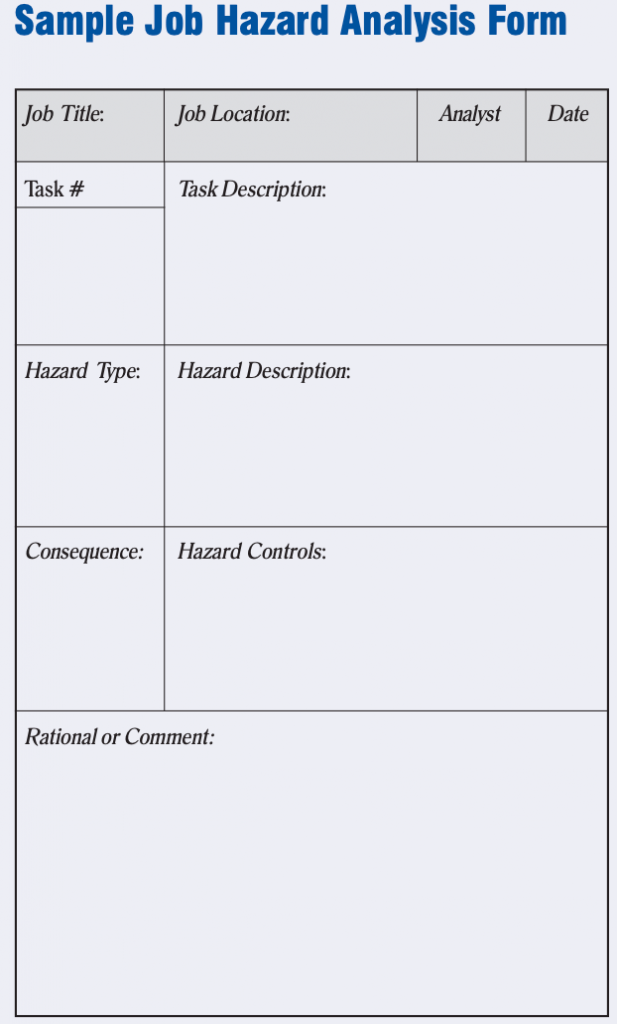

One important activity is to complete a Job Hazard Analysis for all core activities to be performed on the project. OSHA developed a brief booklet to outline an approach for developing a Job Hazard Analysis. The sample template included in this booklet is shown in Figure 2. The core process focuses on breaking down each core activity, e.g., bulk excavation, into specific tasks, e.g., 1) Excavate with excavator; 2) transport truck to excavation location; 3) load truck; and 4) transport truck to external site. For each of these tasks, the team should evaluate the specific hazards for the project, e.g., for task 1 related to excavation, the hazards may include overhead electrical lines in location of excavation, underground utilities in general location of excavation, and maintaining appropriate safety zone in the location of the excavation. Then hazard controls can be put into place to ensure that the hazards are minimized, e.g., marking overhead and underground utilities, etc.

Each trade on the project should be planning these details related to their activities and they should be shared with the lead constructor(s) of the project.

Safety Laws and Regulations

The Occupational Health and Safety Administration (OSHA) was initially formed by

The Impact of High-Quality Safety Programs

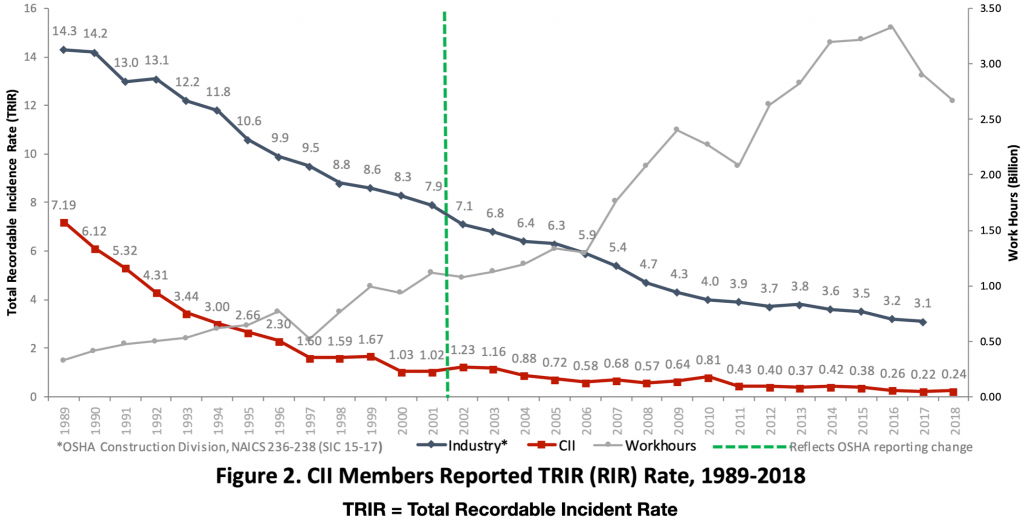

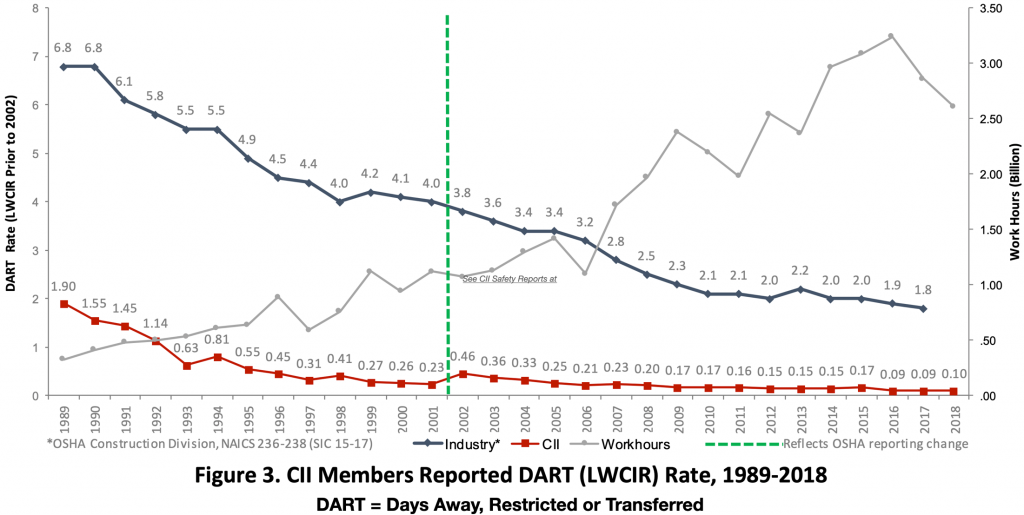

Having a high-quality safety program can significantly impact the health and safety of the workforce through reduced incidents. The Construction Industry Institute (CII) performs and annuals survey of all of their member organizations to collect ‘recordable incidents’ and ‘days away, restricted, or transferred’ ratings. Their members are primarily large constructors and owners, and they tend to have very high-quality safety programs in place. As you can see from the figures below, these companies with high-quality safety programs can significantly (very significantly) outperform the average safety ratings within our industry. This demonstrates that quality safety programs make a difference in reducing safety incidents.

Another study by Leigh (2011) demonstrated that safety incidents carry significant cost impacts. Initially, direct incident costs are associated with the medical expenses of involved workers. But there are many more indirect costs associated with work stoppages and investigations, training and other costs, including damages to property and equipment. These have been estimated to be at least 2.7 times the direct costs (see figure below). Additional indirect costs are associated with any potential fines if the incident has an OSHA violation along with the potential future increase in workers compensation insurance costs.

Figure : Source: https://www.osha.gov/sites/default/files/publications/OSHA3886.pdf

Review Questions

References:

American Society of Civil Engineers (ASCE). ASCE Code of Ethics. Available at https://www.asce.org/career-growth/ethics/code-of-ethics

ASCE. (2017). ASCE Code of Ethics. Available at https://www.asce.org/uploadedFiles/About_ASCE/Ethics/Content_Pieces/Code-of-Ethics-July-2017.pdf

OSHA. (2022). Safety Standard for Construction, Regulation 1926, Available at https://www.osha.gov/laws-regs/regulations/standardnumber/1926

Construction Industry Institute (CII). (2019). CII Safety Summary Report: Summary of CII 2018 Safety Rates. Construction Industry Institute, University of Texas at Austin, Available at https://www.construction-institute.org/securefile?filename=dpc2019_2.pdf#page=3