11 Value Engineering

Learning Objectives

After reading this chapter, you should be able to:

- Define Value Engineering in the context of delivering a construction project.

- Understand the core characteristics of a valuable VE element.

Defining Value

The key word in ‘value engineering’ is ‘value’. One common definition of value is ‘what an owner is willing to pay for’. This leaves a lot to be defined, but certainly clarifies that the project team should be focused on providing benefit to an owner, the entity that is ultimately paying for all costs on a project. This requires the clear interpretation of ‘what provides value to the owner’.

Another way to look at value is through an equation, where value = Function Performance / Resources.

Defining Value Engineering (VE)

Value Engineering (VE) is defined by the Office of Management and Budget as ‘an organized effort directed at analyzing the functions of systems, equipment, facilities, services, and supplies for the purpose of achieving the essential functions at the lowest life-cycle cost consistent with required performance, reliability, quality, and safety. (OMB, Circular No. A-131, 1993). In the Whole Building Design Guide, Cullen (2016) defined Value Engineering as ‘a conscious and explicit set of disciplined procedures designed to seek out optimum value for both initial and long-term investment.’ There are several commonalities in these definitions, including:

- Life-cycle cost: A focus beyond just design and construction costs

- Value optimization: Seeking cost-effective solutions to optimize the value to the owner

- Disciplined process: The team should apply a conscious and disciplined process

It is also important to note items that should not be considered within the definition of value engineering. Cullen (2016) states ‘Value Engineering is not a design/peer review or a cost-cutting exercise.’ This is very important to note since many people may refer to cost-cutting approaches as VE, when they are simply trying to reduce cost and reduce value at the same time.

The Value Engineering Process

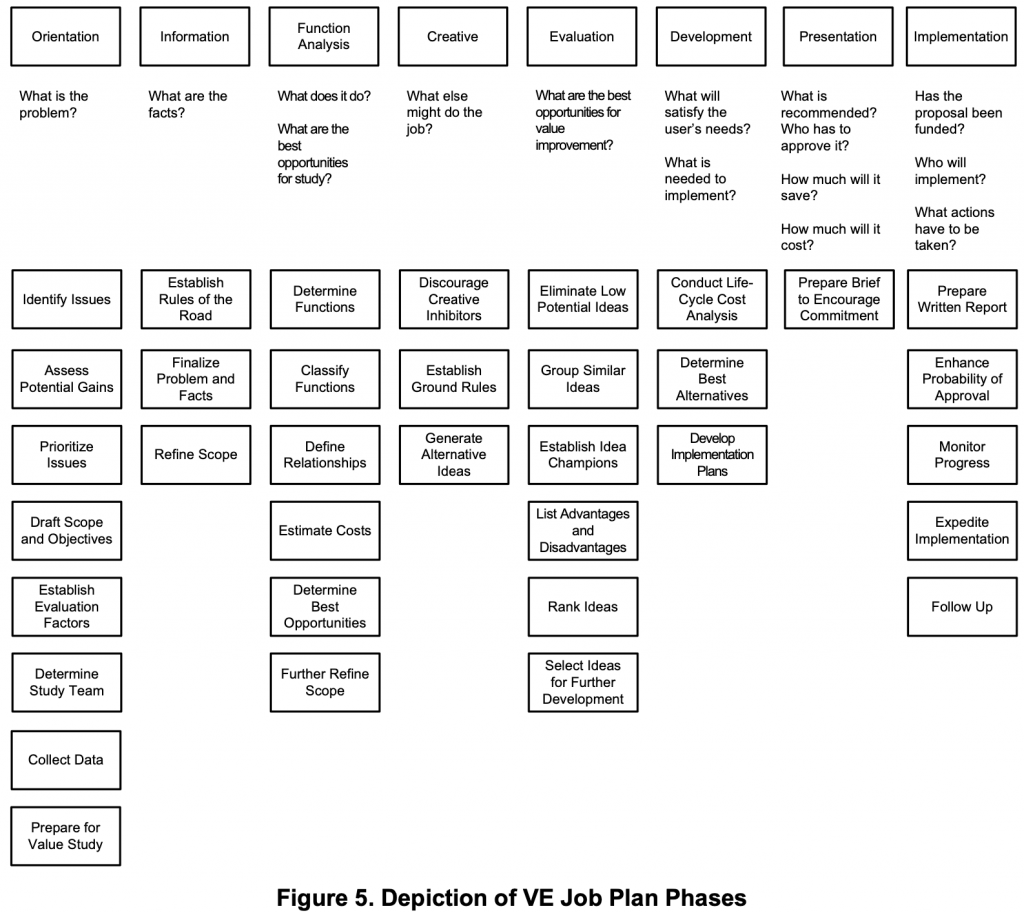

A key element of VE is to ensure that you follow a rigorous, formalized, documented process. There is not one commonly accepted standard process, but there are several documented process descriptions that you can follow. One option is the process defined within the VE

A more concise process has been outlined by SAVE International (https://www.value-eng.org/page/AboutVM) in their Value Methodology Guide. This process contains 8 steps

- Preparation:

- Information:

- Function Analysis:

- Creativity:

- Evaluation:

- Development:

- Presentation:

- Implementation:

The US Army Corps of Engineers has also

as prescribed by SAVE International:

The VE Job Plan follows five key steps:

- Information Phase

- Speculation (Creative) Phase

- Evaluation (Analysis) Phase

- Development Phase (Value Management Proposals)

- Presentation Phase (Report/Oral Presentation)

These five key steps are described as follows:

Examples of Value Engineering Proposals

VE Process Documentation

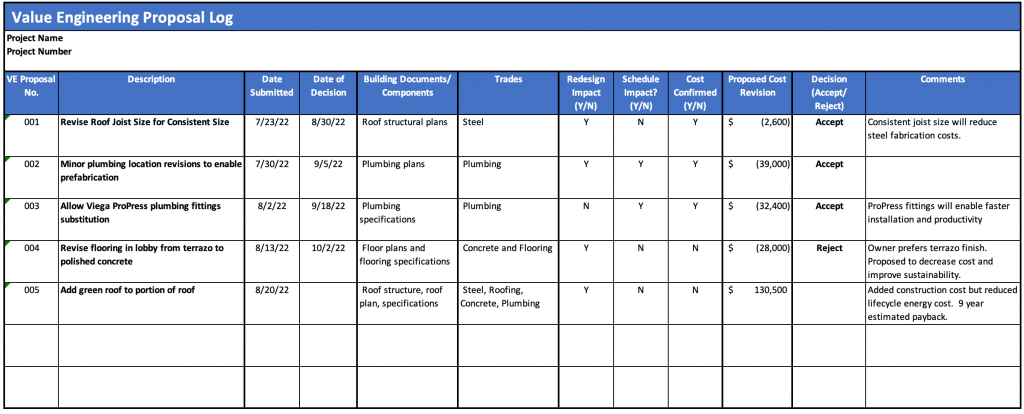

The outcome of the VE process should be monitored and managed. One part of monitoring the process is to maintain a log of the VE suggestions. Most collaborative online project management tools have a location to manage and track VE proposals in an online database. Alternatively, a designer or contractor can track VE proposals in a simple spreadsheet. An example setup with several simple sample proposals is presented in Figure 2.

Review Questions

References and Additional Resources:

Cullen, S. (2016). ‘Value Engineering.’ Whole Building Design Guide, National Institut of Building Sciences. accessed on May 25, 2022, available at https://www.wbdg.org/resources/value-engineering.

Office of Management and Budget. (1993). ‘Subject: Value Engineering.’ Circular No. A-131, available at https://georgewbush-whitehouse.archives.gov/omb/circulars/a131/a131.html

Office of Deputy Assistant Secretary of Defense. (2011).

An organized effort directed at analyzing the functions of systems, equipment, facilities, services, and supplies for the purpose of achieving the essential functions at the lowest life-cycle cost consistent with required performance, reliability, quality, and safety. (Source: OMB, Circular No. A-131, 1993)