Other ODS

Enterprise Info Systems

| Department | Application |

|---|---|

| Sales and Marketing |

|

| Department | Application |

|---|---|

| Sales and Marketing |

|

| Operations |

|

| Manufacturing |

|

Manufacturing Process versus Project

Project based manufacturing views each product as a discrete unit. This allows cost to be aggregated uniquely for that project. Think of a company that build office buildings. each project has a budget and costs are managed for each project/building. some other examples might be movies, homes. Generally these are larger items that are not mass produced. Consulting projects might be another example in your field.

Process manufacturing occurs when there are many identical units produced. Cost are accumulated for a large group or lot of products and then apportioned to each using a formula. You can think about them as a group that is mass produced. A factory may be set up to make a run of Nike shoes all of the same model. Cost of the materials going in would be divided across all of the shoes produced that day to get a cost.

Consider also the speed of the production cycles. The projects usually take longer than the mass produced process manufacturing jobs, and often generate unique data about the project as it progresses through steps (status.) Henry Ford was famous for taking a project based manufacturing process and turning it into a process one.

- Process

- Jell-O Plant

- Brawny Paper Towels

- Toothpaste

- Project

- Construction – Home, Commercial, Solar

- Movie

- Medical Procedure

| Department | Application |

|---|---|

| Sales and Marketing |

|

| Operations |

|

| Manufacturing |

|

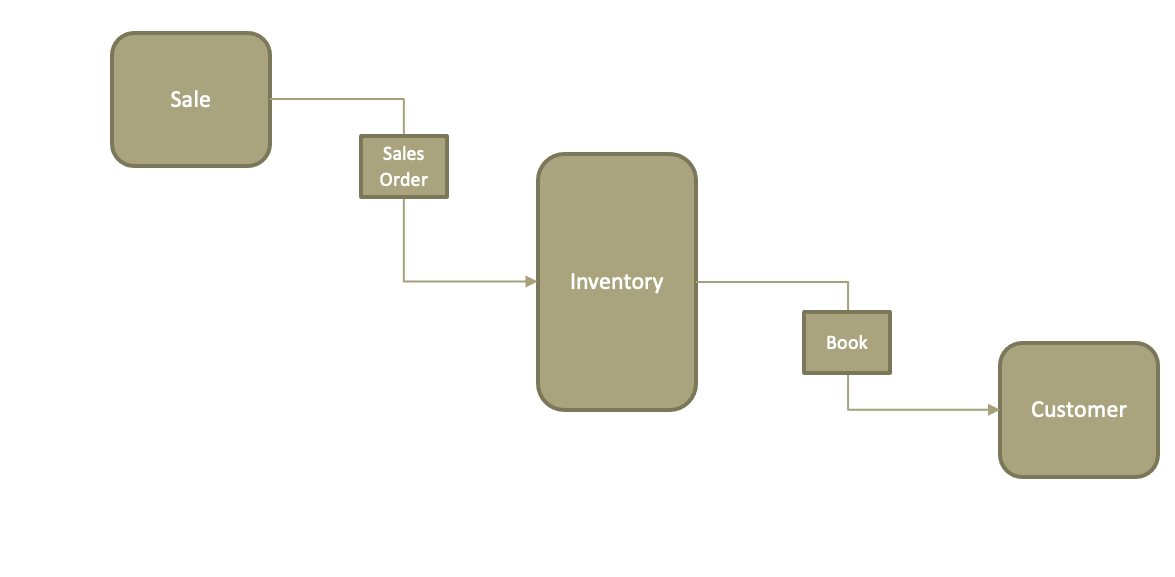

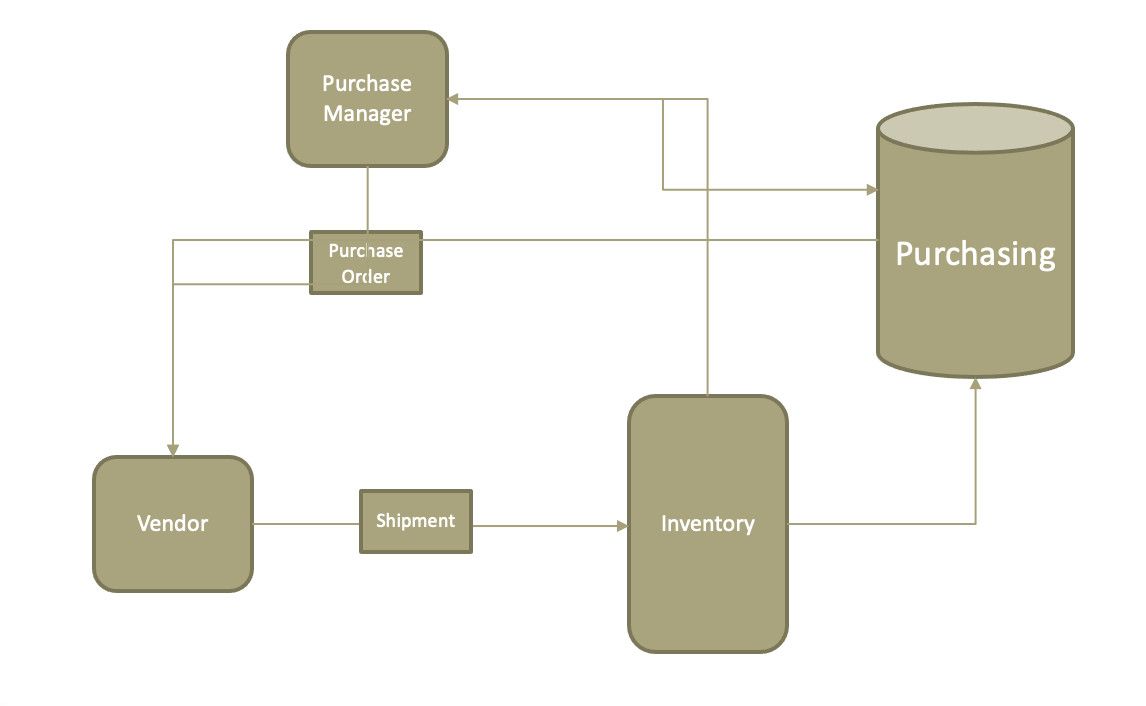

Lets take a look at some the supply chain and inventory. We may hold data about two type of inventory here. raw materials and finished goods. Both may be in the same warehouse. The inventory system generally tells us which is what is stored where and when items need replenishing. Warehouse automation is an interesting field on its own. Basically you are keeping track of what you have and when you need more. and when more comes in, or orders need to be filled the inventory system tells you where to put it away or to pick it for an order. You would expect the functions of the inventory system to be closely tied to purchasing and sales orders.

What are some of the components or entities?

Purchasing / Inventory

Entities

- Vendor Master

- Item Master

- Inventory

- Purchase Requisition

- Purchase Order

- Work Order

Purchasing

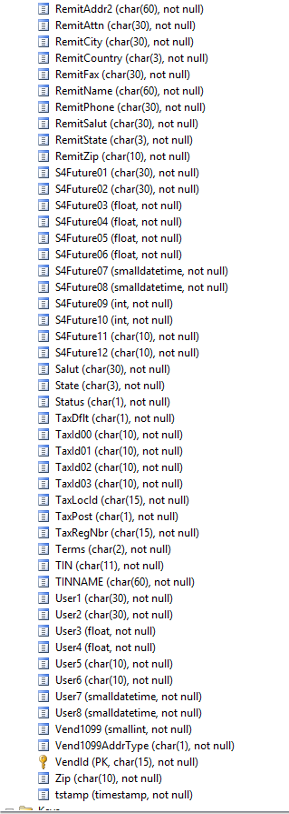

- Vendor Master

- Vendor #

- Vendor Info (address, etc)

- Vendor Contacts

- Vendor Tax Info (payable, Tax area code, Tax Id, VAT)

- Terms Prepayment, net 10, etc

- 1099 Eligibility

- Federal ID

- Our Account #

- Location Code (where vendor ships to)

- Shipping Agent(s)

- Lead Times (shipping)

- Pricing/Discounts

- Product Information

- SKU

- UM or UoM (Unit of Measure)

- Pricing Tiers

- MOQ (Minimum Order Quantity)

- EOQ (Economic Order Quantity)

- Min (Minimum Stock Level)

- Max (Maximum Stock Level)

- Lead Times

- Other

- Requisition

- Purchase Order *

- Work Order

- Receipt

- Invoice

Inventory Processes

Fulfill Order

Replenish

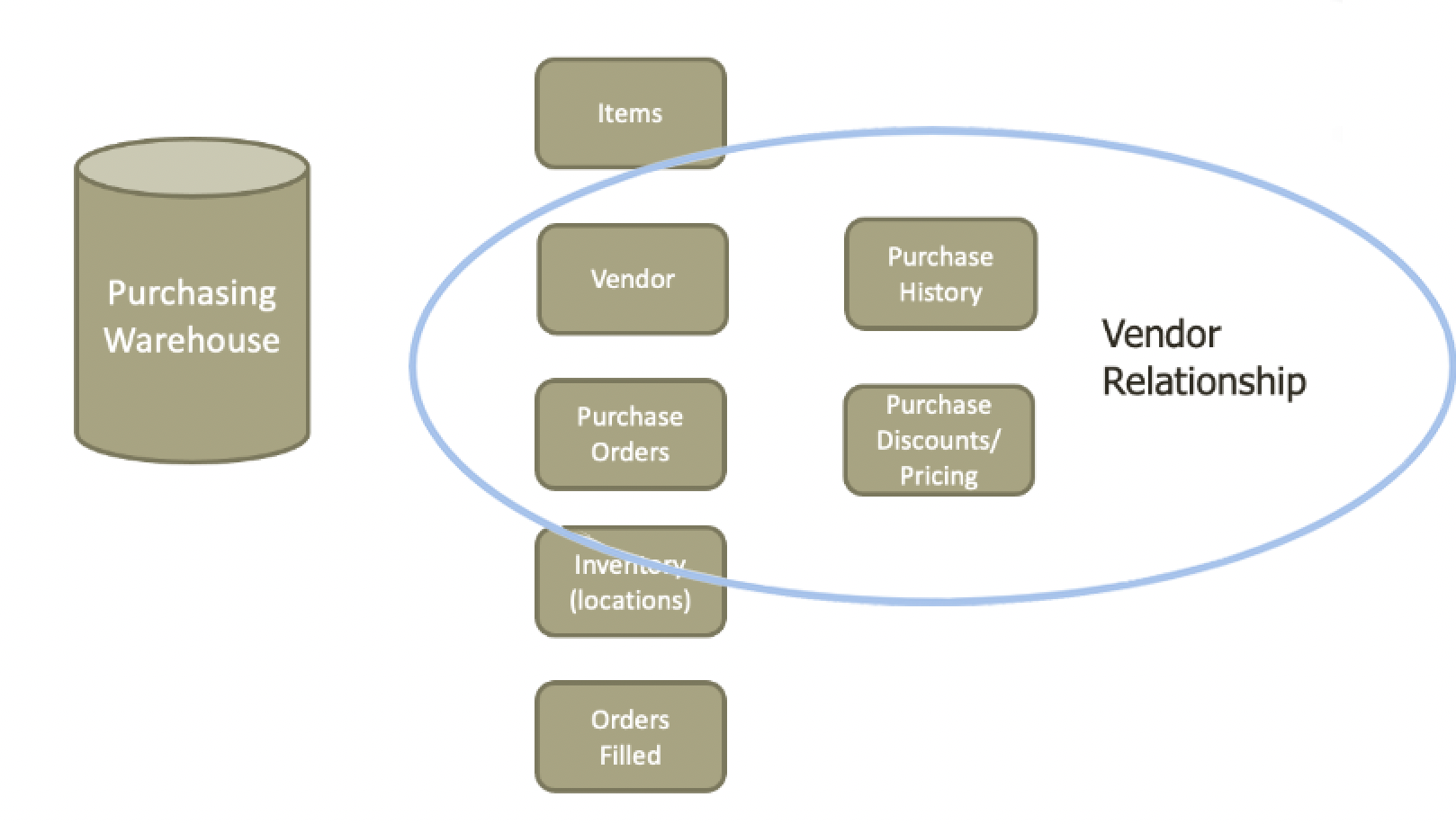

Vendor Relationship

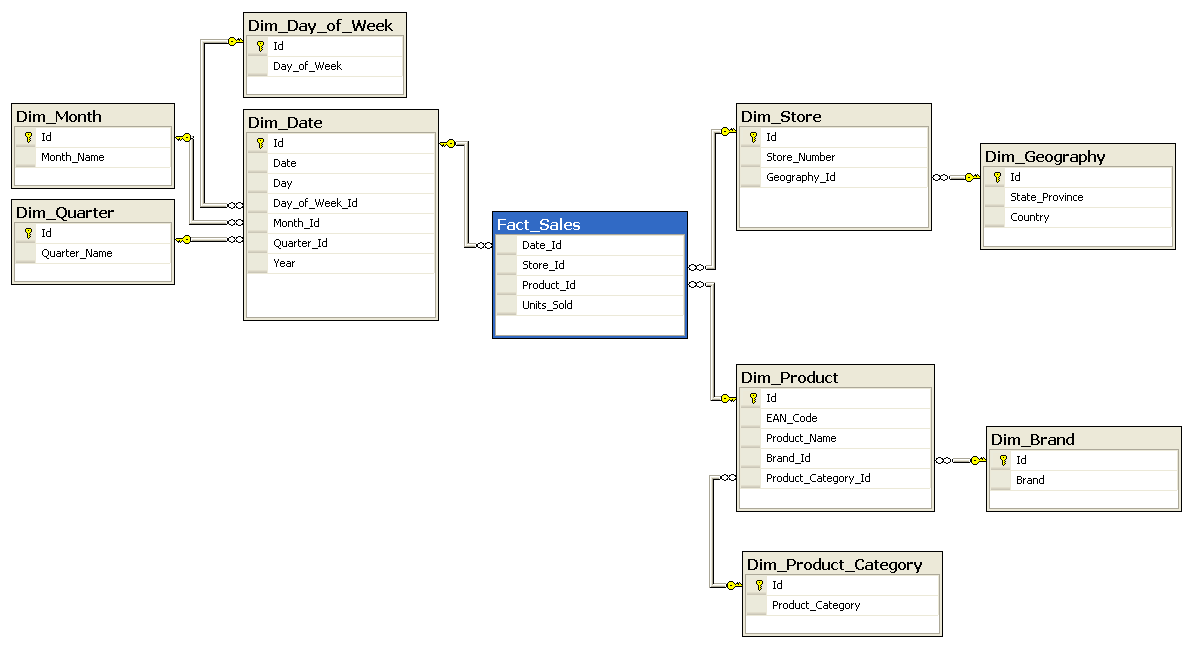

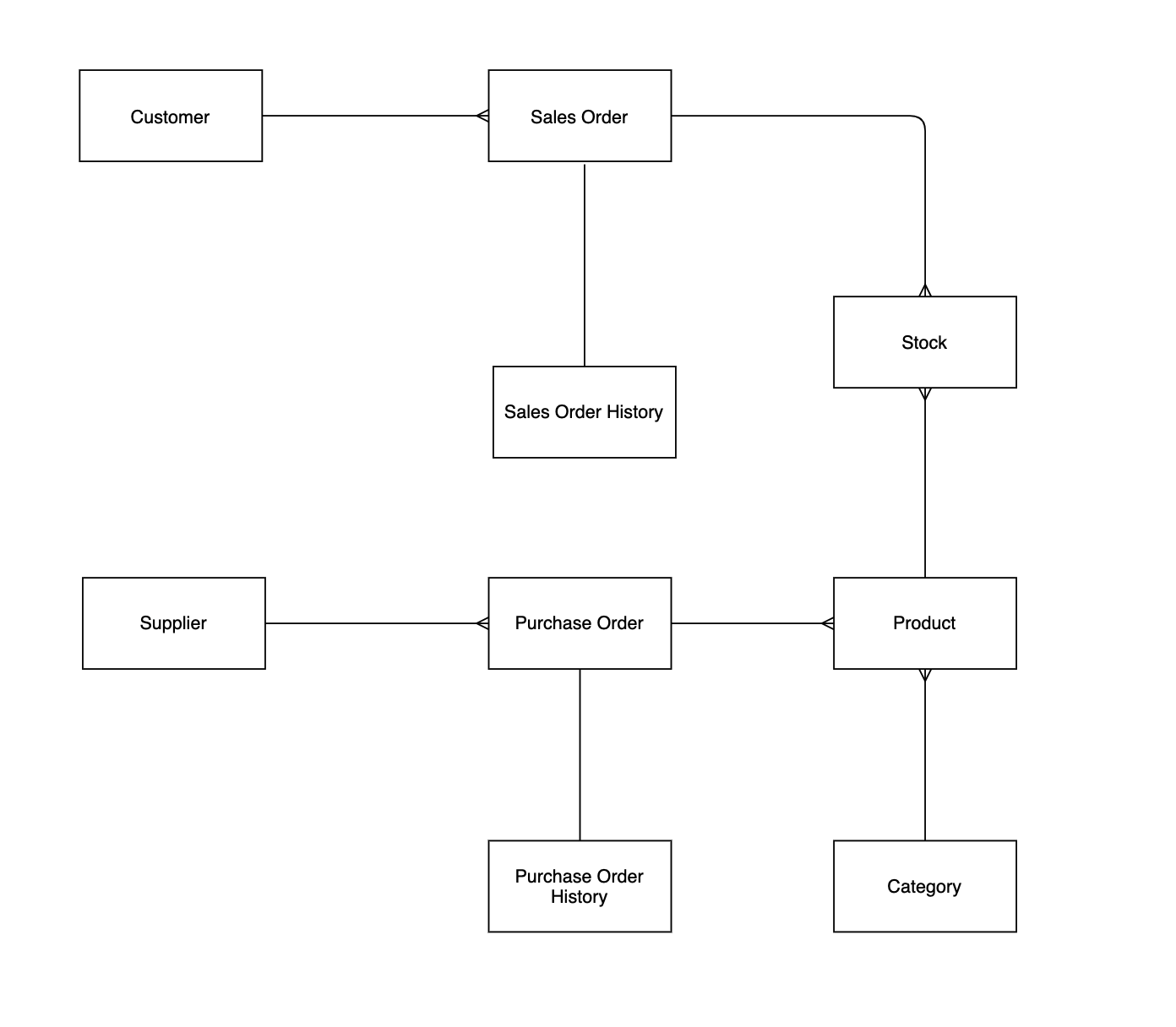

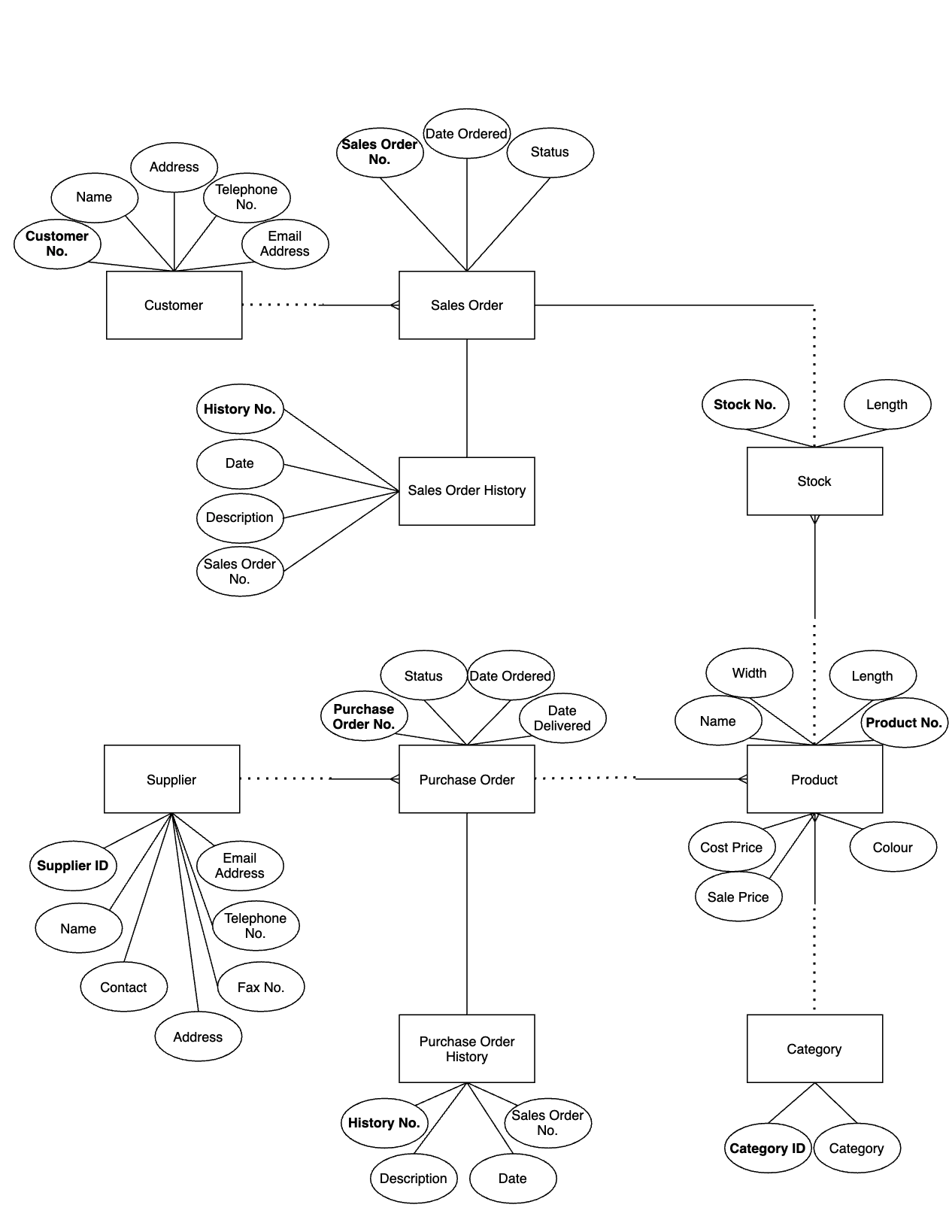

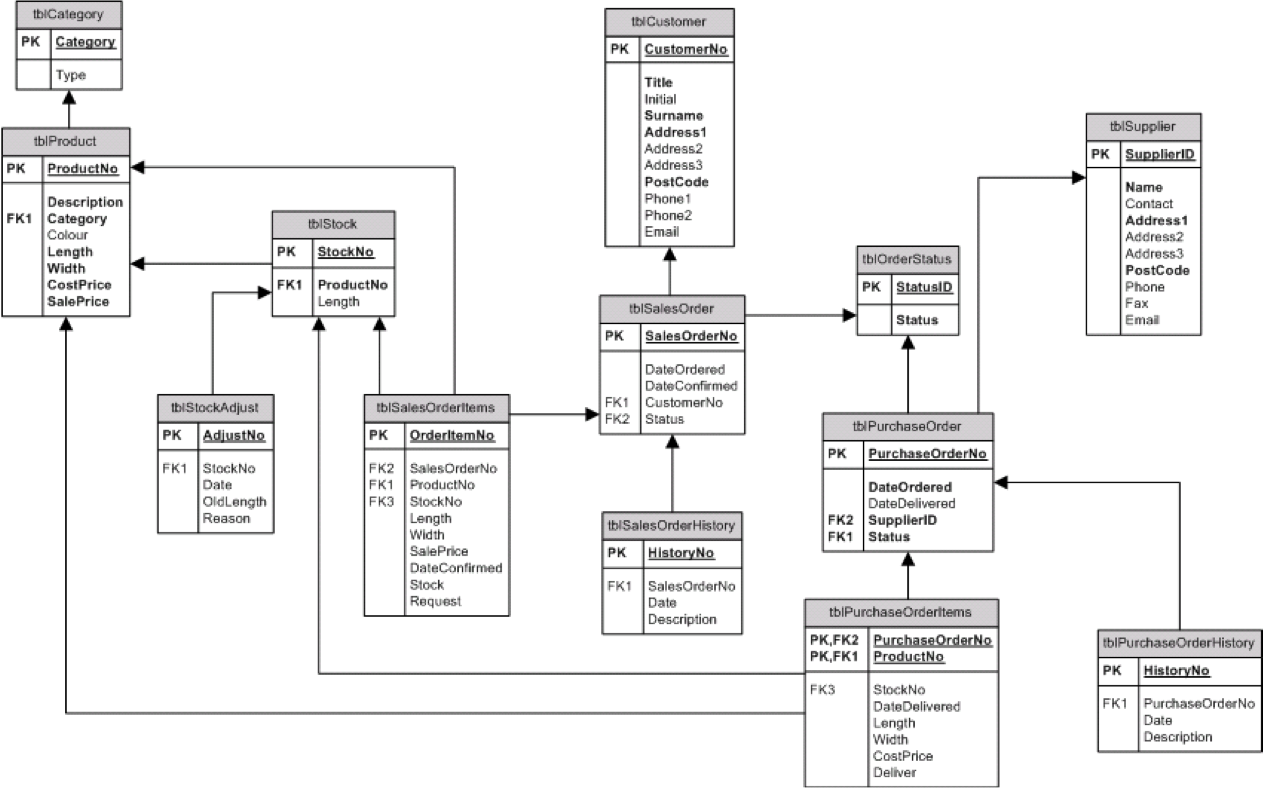

Sample Entity-Relationship Diagrams

An Entity-Relationship (E-R) Diagram helps us to explain, diagrammatically, the overall high-level structure of a database as concluded by Silberschatz (1997). Elmasri & Navathe (1999) state an E-R diagram can be used as a reference to ensure all users’ requirements are met and that no conflicting requirements occur. As the model does not include technical details it was also presented to Carpet World to demonstrate how the system would be implemented. The graphical notation used in the E-R diagram (below) is based on the representation that Rock-Evans (1989) favors and shows the logical structure of the Carpet World database.

Vendor Master

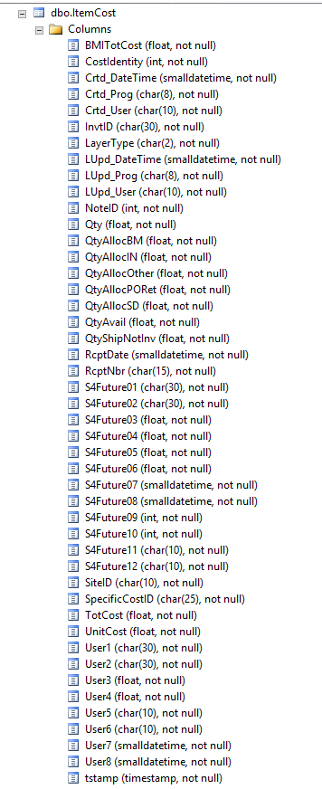

Item Master

Warehouse

- Inventory

- Total Quantity on hand

- Quantity allocated

- Bin #

- On Order (open PO’s)

- Kits

- PO

- Batch Pick

- Pick to Order